Abstract

The selection of a reliable wholesale Fabric Supplier is paramount for any business operating in the textile and apparel industry. A suboptimal choice can lead to significant financial losses, reputational damage, and operational disruptions. This article serves as a comprehensive guide, meticulously outlining seven critical “red flags” that businesses should diligently identify when evaluating potential fabric suppliers. By understanding these warning signs, stakeholders can mitigate risks, foster robust partnerships, and ensure the consistent quality and timely delivery of their raw materials, thereby safeguarding their long-term success.

Table of Contents

- Introduction: Why Vetting Your Wholesale Fabric Supplier is Crucial

- Red Flag 1: The Silent Treatment – Poor Communication and Lack of Transparency

- Red Flag 2: Questionable Quality – Inconsistent Fabric Material and Subpar Samples

- Red Flag 3: Too Good to Be True – Unrealistic Pricing and Unverifiable Claims

- Red Flag 4: Echoes of Dissatisfaction – Negative Reviews and Poor Industry Reputation

- Red Flag 5: Rigidity in Business – Inflexible Minimum Order Quantities (MOQs) and Payment Terms

- Red Flag 6: Missing the Mark – Lack of Specialization or Relevant Certifications

- Red Flag 7: After the Sale – Non-Existent Support and Vague Return Policies

- Making an Informed Choice: Partnering with Reliable Fabric Suppliers for Long-Term Success

Introduction: Why Vetting Your Wholesale Fabric Supplier is Crucial

The foundation of a successful apparel or textile venture rests significantly upon the strength and reliability of its supply chain. Among the most critical components of this chain is the wholesale Fabric Supplier. The decision to partner with a specific supplier is not merely transactional; it is a strategic alliance that directly impacts product quality, production timelines, cost efficiency, and ultimately, brand reputation. Selecting the wrong partner can lead to a cascade of negative consequences, including material defects, production delays, financial losses from unusable inventory, and damage to customer trust.

For businesses aiming for consistent quality and operational smoothness, a thorough vetting process is not just recommended, but essential. Reputable wholesale fabric suppliers can offer competitive pricing and a diverse range of materials that are crucial for various projects (World Linen). Conversely, an unreliable supplier introduces considerable risk. Identifying potential issues early on, before significant investment, is key to safeguarding your business. This article delves into seven distinct “red flags” that serve as clear warning signs, guiding businesses to make informed decisions and avoid costly missteps in their sourcing journey. Finding the right fabric supplier is a crucial step in the purchasing process, emphasizing the need for diligent research and assessment (Techpacks).

Red Flag 1: The Silent Treatment – Poor Communication and Lack of Transparency

Effective communication is the cornerstone of any productive business relationship. When evaluating a potential wholesale fabric materials supplier, a discernible lack of responsiveness or clarity in communication should be considered a significant red flag. This can manifest in several ways: delayed replies to inquiries, evasive answers regarding product specifications, or a general reluctance to provide detailed information. Poor communication is a classic warning sign, often leading to misunderstandings and escalating conflict (Couples Learn).

Beyond responsiveness, transparency is equally vital. Suppliers who are vague about their pricing structures, fail to disclose potential hidden fees, or operate with opaque business practices raise serious concerns. For instance, an inability or unwillingness to provide a clear breakdown of costs, including shipping, taxes, and potential surcharges, indicates a lack of transparency that can lead to unexpected financial burdens. Similarly, if a supplier is reluctant to share information about their manufacturing processes, material sourcing, or quality control measures, it could suggest underlying issues. Stonewalling or consistent miscommunication are critical indicators that communication is breaking down, pointing to potential future difficulties (Eternity Rose). A reliable supplier should be forthright, proactive, and willing to engage in open dialogue at every stage of the engagement.

Red Flag 2: Questionable Quality – Inconsistent Fabric Material and Subpar Samples

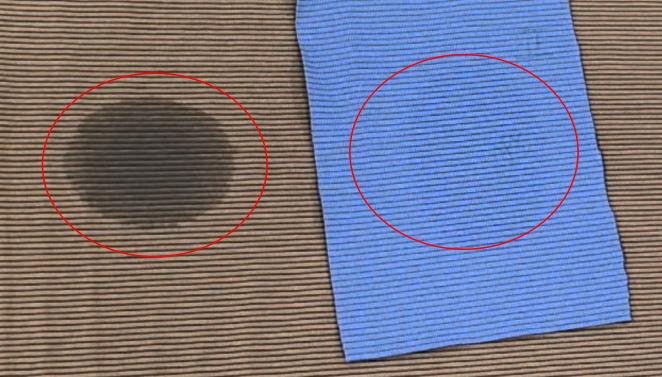

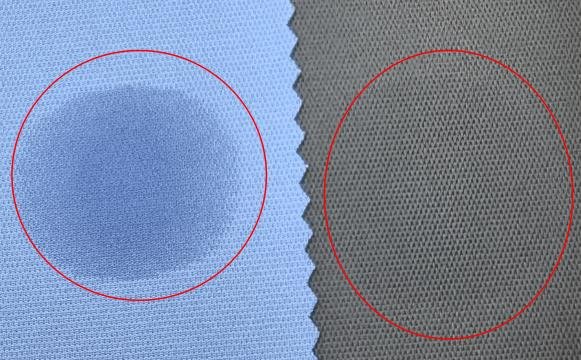

The quality of the garment fabric directly dictates the quality of the final product. A significant red flag emerges when a potential supplier demonstrates inconsistencies in material quality or provides samples that do not meet expected standards. This could involve variations in fabric weight, weave, color consistency, or durability between different batches or even within the same sample order. Inconsistent quality control is a clear warning sign from a supplier (Field Fabric Journal).

When requesting samples, it is imperative to scrutinize them for any imperfections, flaws, or deviations from the agreed-upon specifications. If the initial samples are subpar, exhibit poor finishing, or do not accurately represent the desired cloth material, it is a strong indicator of potential quality control issues in bulk orders. Furthermore, a supplier’s inability to consistently provide fabric that matches a previously approved sample, or their hesitation to offer multiple samples for quality verification, signals unreliability. Understanding how to recognize high-quality fabrics and the associated warning signs is crucial for sourcing (YouTube – Spotting Quality in Clothing). Businesses must prioritize suppliers with rigorous quality assurance processes and a demonstrated track record of delivering consistent, high-standard materials.

Red Flag 3: Too Good to Be True – Unrealistic Pricing and Unverifiable Claims

While competitive pricing is desirable, offers that appear “too good to be true” often conceal underlying problems. If a wholesale fabric supplier presents prices significantly lower than the industry average for comparable materials, it warrants immediate suspicion. Such unrealistic pricing can indicate several critical issues:

Hidden Costs: The initial low price may exclude essential fees such as shipping, tariffs, customs duties, or handling charges, which are revealed only later in the purchasing process.

Inferior Material Quality: Unusually low prices often correlate with a compromise in material quality, leading to the use of cheaper, less durable, or substandard fabrics that may not meet product requirements or safety standards.

Unreliable Delivery: Suppliers offering exceptionally low prices might cut corners on logistics, resulting in chronic delays, incorrect orders, or even non-delivery, severely impacting production schedules.

Unverifiable Claims: Be wary of suppliers who make grandiose or unsubstantiated claims about their capabilities, certifications, or material properties without providing tangible proof. For example, claims of eco-friendliness without credible certifications can be a form of greenwashing (Rainforest Alliance).

These “too-good-to-be-true promises” are a common red flag in various industries, signaling potential scams or deceptive practices (Keitaro Blog). Always conduct thorough due diligence, compare quotes from multiple suppliers, and request detailed breakdowns of all costs to ensure transparency and avoid unexpected expenses or quality compromises.

Red Flag 4: Echoes of Dissatisfaction – Negative Reviews and Poor Industry Reputation

In the digital age, a supplier’s reputation is often publicly accessible through online reviews, forums, and industry discussions. A proliferation of negative feedback or a generally poor industry reputation is a serious red flag that should not be overlooked. Consistent negative comments regarding service, product quality, delivery issues, or ethical concerns are strong indicators of potential problems.

Businesses should proactively conduct thorough online research, checking platforms such as Google Reviews, industry-specific forums, social media, and business directories. While occasional negative reviews are not uncommon, a pattern of widespread complaints, particularly those mentioning similar issues across multiple customers, suggests systemic problems. These online reputation red flags warrant immediate attention (TheBestReputation). Furthermore, seeking testimonials from other businesses or industry peers can provide valuable insights into a supplier’s track record and reliability. A consistent stream of negative feedback, particularly concerning communication or the absence of regular feedback, is a significant warning sign (LinkedIn – Nick Abraham). Disregarding these “echoes of dissatisfaction” can lead to significant operational hurdles and potential harm to your own brand.

Red Flag 5: Rigidity in Business – Inflexible Minimum Order Quantities (MOQs) and Payment Terms

Flexibility in business operations is crucial, especially for evolving businesses or those dealing with varying production scales. A red flag arises when a wholesale fabric supplier exhibits excessive rigidity concerning Minimum Order Quantities (MOQs) and payment terms. While MOQs are a standard practice to ensure profitability for suppliers, an unwillingness to negotiate reasonable quantities, even for initial or smaller-scale orders, can severely hinder a buyer’s operational flexibility and inventory management. This is particularly true for small businesses, where high MOQs can be a significant hurdle (Deliver and Store).

Similarly, overly restrictive payment terms, such as demanding 100% upfront payment for new clients without a credit history, or offering no flexibility in payment schedules, can strain a buyer’s cash flow. While suppliers have legitimate reasons for their terms, an absolute refusal to discuss or adjust terms based on business needs or volume can indicate a lack of customer-centricity or financial instability on the supplier’s part. Understanding the challenges of MOQs is important for any business relationship (Red Stag Fulfillment). A good partner should be willing to engage in a dialogue to find mutually beneficial solutions that support the buyer’s business objectives.

Red Flag 6: Missing the Mark – Lack of Specialization or Relevant Certifications

The textile industry is vast, with numerous specialized materials and production processes. A significant red flag appears when a potential fabric supplier lacks specific expertise in the desired materials or fails to provide necessary quality and sustainability certifications. If a supplier claims to offer everything from delicate silk to heavy-duty denim without demonstrating deep knowledge or a clear focus on a particular niche, it might indicate a generalist approach that could compromise quality in specialized areas. For instance, if your business requires wholesale anti-sweat fabric for performance apparel, a supplier without proven experience or a dedicated product line in technical textiles might struggle to meet precise specifications.

Furthermore, in today’s market, certifications are paramount for verifying quality, ethical practices, and environmental compliance. A lack of relevant certifications, such as Oeko-Tex, GOTS (Global Organic Textile Standard), ISO standards, or fair-trade accreditations, should raise concerns. These certifications provide objective proof that the supplier adheres to industry benchmarks and responsible manufacturing practices. A missing specialization or relevant certifications can be a red flag in various professional contexts (LinkedIn – Resume Red Flags). Without them, verifying claims about material composition, antibacterial, or sustainable sourcing becomes difficult, increasing the risk for the buyer.

Red Flag 7: After the Sale – Non-Existent Support and Vague Return Policies

The business relationship with a supplier does not conclude upon delivery of the order; robust post-purchase support is crucial, especially for bulk fabric material orders. A critical red flag is the absence of clear return policies, vague warranty details, or non-existent customer support after the sale. Issues can arise post-delivery, such as discrepancies in quantity, quality deviations, or damage during transit. Without a clearly defined and transparent return or dispute resolution process, businesses can face significant losses and operational headaches.

Suppliers who are difficult to reach for post-purchase inquiries, who provide evasive answers regarding problem resolution, or whose policies are intentionally ambiguous, indicate a lack of commitment to customer satisfaction. A legitimate supplier will have a well-documented return policy and a responsive customer service team to address any concerns promptly. Issues like inadequate vendor identification information or a non-existent address or phone number can be fraud red flags (DoDIG.mil), though in this context, they point more to unreliability. Similarly, while sellers may state “no returns,” there’s typically recourse if the item is misrepresented or faulty, highlighting the importance of clear policies (Reddit – Mercari). Always ensure that the supplier offers comprehensive post-sales support and clear, fair policies to protect your investment.

Image: Individuals examining fabric samples, emphasizing the importance of quality inspection.

To aid in the selection process, here’s a summary of the red flags and their potential impact:

| Red Flag Category | Specific Warning Signs | Potential Business Impact | Actionable Advice |

|---|---|---|---|

| Communication & Transparency | Slow responses, vague answers, hidden fees, unclear processes. | Production delays, unexpected costs, misunderstandings, legal issues. | Prioritize suppliers with clear communication channels, request detailed quotes, and review all terms. |

| Product Quality | Inconsistent samples, poor material quality, deviations from specifications. | Subpar final products, increased waste, returns, damage to brand reputation. | Demand multiple samples, conduct rigorous quality checks, visit facilities if possible. |

| Pricing & Claims | Unrealistically low prices, unverifiable claims, lack of proof for certifications. | Compromised quality, hidden costs, fraudulent practices, supply chain instability. | Compare industry averages, request comprehensive cost breakdowns, verify all claims and certifications. |

| Reputation & Reviews | Numerous negative online reviews, widespread industry dissatisfaction. | Operational hurdles, unreliable deliveries, ethical concerns, reputational risks. | Thoroughly research online reviews, seek industry referrals, engage in due diligence. |

| Business Rigidity | Inflexible MOQs, non-negotiable or restrictive payment terms. | Cash flow strain, inventory management difficulties, limited operational flexibility. | Negotiate terms, assess alignment with business scale, explore alternative payment structures. |

| Specialization & Certifications | Lack of expertise in specific materials, absence of relevant quality/sustainability certifications. | Inability to meet specialized needs, non-compliance issues, ethical concerns, product failures. | Verify specialization, request copies of all relevant certifications, inquire about production processes. |

| Post-Sale Support | Vague return policies, non-existent customer support, unclear warranty details. | Financial losses on faulty goods, unresolved disputes, operational disruptions. | Review return/warranty policies in detail, test customer support responsiveness, include terms in contracts. |

Making an Informed Choice: Partnering with Reliable Fabric Suppliers for Long-Term Success

The process of selecting a wholesale fabric supplier is a critical strategic decision that demands meticulous attention to detail and a proactive approach to risk assessment. By understanding and actively scrutinizing for the seven red flags outlined—poor communication, questionable quality, unrealistic pricing, negative reputation, business rigidity, lack of specialization, and inadequate post-sale support—businesses can significantly reduce their exposure to costly mistakes and operational disruptions.

Partnering with reliable fabric suppliers fosters a symbiotic relationship built on trust and mutual benefit. Open communication, regular feedback, and mutual trust are essential ingredients for long-term success (Textile). A trustworthy supplier will not only provide consistent quality and competitive pricing but also offer transparent practices, flexible terms, and dependable support, all of which are essential for maintaining a business’s reputation and profitability (Source of Fabric). The initial investment of time and resources into thorough vetting will yield substantial returns in the form of a stable supply chain, superior product quality, and the sustained growth of your garment business. Choosing wisely is not just about avoiding bad experiences; it is about laying a solid foundation for enduring success.

Sources

Looking For Textile Supplier? Get Wholesale Price From Us Now

![[JuncoMaterials]The Ultimate Guide to Finding a Fabric Supplier for Your New Clothing Brand](https://materials.juncosports.com/wp-content/uploads/2025/07/image-11.jpg)

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)