Abstract

This comprehensive guide provides fundamental, step-by-step guidance for new small businesses, including startup fashion brands and small Etsy shop owners, on how to effectively begin sourcing wholesale fabric materials. It addresses common concerns regarding the procurement process, typical mistakes, and the critical importance of identifying and collaborating with reliable partners. By navigating through essential considerations from defining specific fabric needs to fostering long-term supplier relationships, this article aims to empower entrepreneurs to make informed decisions that ensure product quality, operational efficiency, and sustainable growth.

Table of Contents

- Introduction: Why Your Small Business Needs Wholesale Fabric Materials

- Understanding Your Needs: Defining Fabric Types, Quality, and Quantity

- Navigating the Sourcing Landscape: Where to Find Reputable Wholesale Fabric Materials Suppliers

- Essential Questions to Ask When Vetting Wholesale Fabric Materials Providers

- The Procurement Process: From Sample to Bulk Purchase of Garment and Cloth Material

- Avoiding Common Pitfalls When Buying Wholesale Anti-Sweat Fabric and Other Materials

- Building Long-Term Relationships with Your Fabric Suppliers

- Conclusion: Empowering Your Business with the Right Wholesale Fabric Materials

Introduction: Why Your Small Business Needs Wholesale Fabric Materials

For burgeoning fashion brands, small-scale designers, or artisanal craft businesses, transitioning from retail fabric purchases to wholesale sourcing represents a pivotal step towards scalability and profitability. Acquiring wholesale fabric materials offers a multitude of strategic advantages that are indispensable for long-term business viability.

Firstly, buying fabric in bulk provides significant cost savings, directly impacting your profit margins. As businesses grow, the ability to reduce per-unit material costs becomes crucial for competitive pricing and overall financial health (Spandex Warehouse). Beyond economic benefits, wholesale purchasing opens access to a broader selection of materials and greater availability, allowing businesses to diversify their product lines and respond effectively to market trends (Source of Fabric). This access to a wider range of options, including specialized textiles, can differentiate your products and cater to niche demands, such as performance wear requiring moisture-wicking properties. Furthermore, establishing wholesale accounts ensures a consistent supply of materials, mitigating the risks associated with stock shortages and enabling smoother production cycles. This foundational understanding of wholesale benefits sets the stage for a systematic approach to fabric sourcing.

Understanding Your Needs: Defining Fabric Types, Quality, and Quantity

Before embarking on the search for suppliers, a clear understanding of your specific fabric requirements is paramount. This involves a precise definition of the fabric types, desired quality standards, and necessary quantities.

Defining Fabric Types

The selection of fabric profoundly influences the final product’s aesthetics, functionality, and comfort. Different projects necessitate distinct materials. For instance, a basic T-shirt might require a soft cotton jersey, while activewear demands performance fabrics. Common fabric types include:

- Cotton: Versatile, breathable, and widely used for various apparel and home goods. It can be blended with elastane for stretch or used in absorbent forms like terry cloth (Hawthorn Intl).

- Polyester: Known for durability, wrinkle resistance, and often used in blends or for specialized applications like outerwear.

- Wool: A natural fiber prized for warmth, resilience, and moisture-wicking properties, historically used for sturdy garments (Hawthorn Intl).

- Silk: Luxurious, smooth, and breathable, ideal for high-end apparel.

- Blends: Combinations of fibers to achieve specific characteristics, such as cotton-polyester blends for durability and comfort.

Understanding the pros, cons, and popular uses of various fabric types is essential for informed decision-making (Fabric Mill). Consider the garment’s purpose, desired drape, texture, and care requirements. For example, if you are creating athletic wear, you will need to prioritize fabrics that offer specific performance attributes, such as moisture management or stretch.

Assessing Quality

Fabric quality directly impacts your product’s longevity, appearance, and customer satisfaction. Key quality considerations include:

- Durability: How well the fabric withstands wear and tear, washing, and fading.

- Hand/Feel: The tactile sensation of the fabric, which influences comfort and drape.

- Colorfastness: The fabric’s ability to retain its color without bleeding or fading after washing or exposure to light.

- Consistency: Ensuring uniformity in weave, weight, and color across different bolts or dye lots.

Requesting samples and conducting preliminary tests (e.g., shrinkage, color bleed) is crucial for validating quality claims.

Determining Quantity

Quantifying your needs involves more than just estimating sales. Most garment fabric suppliers have Minimum Order Quantities (MOQs), which can range from a few yards to thousands.

- Initial Orders: For startups, MOQs can be a significant hurdle. Start with realistic production goals.

- Scalability: Consider future growth. While initial orders might be smaller, assess if suppliers can accommodate larger volumes as your business expands.

- Wastage: Factor in a small percentage for cutting errors or design adjustments.

Aligning your quantity needs with supplier MOQs early in the process avoids potential disappointments and ensures a smoother procurement of your desired cloth material.

Navigating the Sourcing Landscape: Where to Find Reputable Wholesale Fabric Materials Suppliers

Identifying reliable sources for wholesale fabric materials is a critical step that underpins the success of your small business. The sourcing landscape offers diverse channels, each with its own advantages.

Online Marketplaces and Directories

Online platforms are often the first stop for many new businesses due to their vast selection and accessibility. Websites like Alibaba, Fibre2Fashion, and specialized fabric sourcing directories allow you to browse a wide array of fabrics, compare prices, and directly communicate with suppliers (MakeMine). These platforms facilitate the initial research phase, helping you discover potential partners globally. However, due diligence is paramount to filter out less reputable entities.

Trade Shows and Fabric Expos

Attending industry-specific trade shows and fabric expos provides an invaluable opportunity for direct engagement with suppliers (Source of Fabric). These events allow you to:

- Physically inspect fabric samples, assessing their hand, drape, and true color.

- Discuss specific requirements face-to-face, fostering clearer communication.

- Negotiate terms directly and build rapport.

- Network with other industry professionals and gain insights into emerging trends.

While requiring travel and time investment, the benefits of in-person vetting often outweigh the costs, offering a more tactile and personal sourcing experience.

Direct Manufacturers or Agents

For businesses with specific design needs or higher volume requirements, engaging directly with fabric manufacturers or their authorized agents can be advantageous. This approach often allows for custom fabric development, better pricing at scale, and a deeper understanding of the production process. However, it typically involves higher MOQs and more complex communication.

Regardless of the channel chosen, the emphasis must always be on identifying trustworthy suppliers. Fabric sourcing is not merely about finding a material; it involves selecting the ideal material, identifying trustworthy suppliers, and negotiating the best deal to ensure smooth production (Sino-Silk). Thorough research, reviewing testimonials, and requesting references are essential steps in this vetting process.

Essential Questions to Ask When Vetting Wholesale Fabric Materials Providers

Vetting potential wholesale fabric suppliers thoroughly is non-negotiable for mitigating risks and ensuring a consistent supply of quality materials. Engaging in detailed discussions and asking pointed questions can reveal much about a supplier’s reliability, capabilities, and business practices. Below is a table outlining crucial questions to ask:

| Category | Essential Question to Ask | Why It Matters for Your Business |

|---|---|---|

| Minimum Order Quantities (MOQs) | What are your Minimum Order Quantities (MOQs) for different fabric types? | Ensures compatibility with your production scale and budget. High MOQs can prevent startups from sourcing desired materials. |

| Pricing & Discounts | What is your pricing structure, and do you offer volume discounts? | Helps in budget planning and understanding potential cost savings as your business grows. Clarifies all-inclusive pricing. |

| Sample Availability | Do you provide fabric or material samples, and what is the cost and lead time for samples? | Crucial for physical evaluation of fabric quality, color, and suitability before committing to a bulk order. |

| Lead Times | What are the typical lead times for sample production and bulk orders once payment is confirmed? | Essential for production scheduling and meeting delivery deadlines for your products. Delays can disrupt your supply chain. |

| Payment Terms | What are your payment terms (e.g., upfront, net 30) and accepted payment methods? | Impacts your cash flow management. Understanding terms prevents misunderstandings and financial bottlenecks. |

| Quality Control (QC) | How do you ensure product quality, and do you have any certifications (e.g., Oeko-Tex, GOTS)? | Verifies the supplier’s commitment to quality standards and compliance with ethical or environmental regulations if applicable (MakersRow). |

| Return/Exchange Policy | What is your policy for defective or incorrect fabric shipments? | Provides a safety net in case of issues, protecting your investment and ensuring you receive usable materials. |

| Shipping & Logistics | What are your shipping options, costs, and typical delivery times to my location? | Affects total cost and delivery schedule. Clarifies who is responsible for shipping risks (Incoterms). |

Asking these questions upfront facilitates transparency and helps you assess if a potential supplier aligns with your business’s operational needs and values. A supplier’s willingness to provide clear, detailed answers often indicates their professionalism and reliability.

The Procurement Process: From Sample to Bulk Purchase of Garment and Cloth Material

The procurement of garment fabric and cloth material involves a structured process, moving from initial sampling to the final bulk purchase. Adhering to these steps ensures quality control and efficient supply chain management.

Step 1: Market Research and Supplier Identification

As previously discussed, the first phase involves extensive market research to identify potential suppliers that meet your initial criteria (Procurement Tactics). This includes evaluating their product range, reputation, and general capabilities.

Step 2: Requesting and Evaluating Samples

Once potential suppliers are identified, the crucial next step is to request samples of the specific fabrics you are considering. Physical evaluation is indispensable. Assess the sample for:

- Hand and Drape: How the fabric feels and how it hangs.

- Color Accuracy: Comparing the physical sample to digital swatches or your desired palette.

- Weight and Construction: Verifying the weave, knit, or finish.

- Suitability for Intended Use: Testing for stretch, absorbency, or breathability if relevant to your product.

Step 3: Detailed Information Gathering and RFQ

After sample evaluation, gather detailed information from the selected suppliers. This might involve formal Requests for Quotation (RFQs) where you outline your specific needs, quantities, and quality expectations (Procurement Tactics). This step ensures all stakeholders—from designers to production teams—are aligned on the fabric specifications.

Step 4: Negotiation and Terms Confirmation

Once satisfied with samples and quotes, engage in negotiations regarding pricing, MOQs, payment terms, and lead times. Ensure all agreed-upon terms are clearly documented in a purchase order or contract. Payment terms typically range from upfront deposits to net 30/60 days, depending on the supplier relationship and order size.

Step 5: Placing the Bulk Order

With terms agreed upon, proceed to place your bulk order. This usually involves an official Purchase Order (PO) detailing quantities, fabric specifications, agreed prices, and delivery schedules. Maintaining clear communication with your supplier throughout the production phase is vital for monitoring progress and addressing any potential issues promptly.

Step 6: Quality Control and Shipping Logistics

Before final shipment, discuss the supplier’s quality control procedures. Some businesses opt for third-party inspections for large orders. Finally, arrange shipping, paying close attention to Incoterms (International Commercial Terms) which define responsibilities for shipping costs and risks. Understand customs procedures and potential duties to avoid unexpected delays or costs upon arrival. This diligent procurement process is key to sourcing high-quality materials while optimizing costs (MakeMine).

![[JuncoMaterials]The Ultimate Guide to Finding a Fabric Supplier for Your New Clothing Brand](https://materials.juncosports.com/wp-content/uploads/2025/07/image-12.jpg)

Avoiding Common Pitfalls When Buying Wholesale Anti-Sweat Fabric and Other Materials

Navigating the wholesale fabric materials market can present various challenges for new buyers. Awareness of common pitfalls and proactive mitigation strategies can save significant time, money, and frustration, especially when dealing with specialized textiles like wholesale anti-sweat fabric.

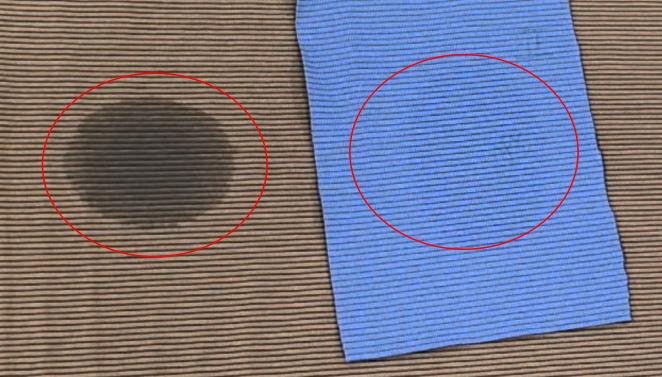

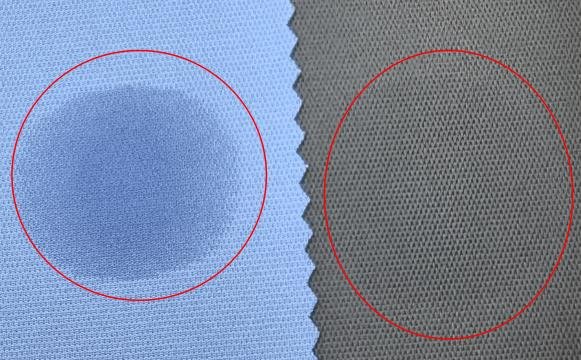

Not Thoroughly Checking Samples

One of the most frequent mistakes is neglecting to order or adequately test fabric samples. Relying solely on digital images or descriptions can lead to disappointment upon receiving bulk orders. Always:

- Order swatches or small cuts: Verify color accuracy, texture, weight, and drape in person.

- Perform simple tests: Check for shrinkage (wash and dry as intended), colorfastness (rub with a damp white cloth), and durability if applicable (Spandex Warehouse). For anti-sweat fabrics, test their wicking capabilities by applying a drop of water.

- Evaluate against intended use: Ensure the fabric performs as expected for your product.

Ignoring Minimum Order Quantities (MOQs)

New businesses often underestimate the impact of MOQs. Trying to negotiate significantly below a supplier’s stated MOQ can lead to higher per-unit costs or outright rejection. Conversely, ordering far too much to meet an MOQ can result in excess inventory, tying up capital and storage space. Plan your production realistically and seek suppliers whose MOQs align with your current and projected needs.

Poor Communication with Suppliers

Ambiguity in communication can lead to significant errors. Ensure:

- Clear specifications: Provide precise details on fabric type, color codes (e.g., Pantone), weight, and finishes.

- Written records: Confirm all agreements, changes, and important discussions in writing (email is ideal).

- Cultural awareness: Be mindful of time differences and potential cultural nuances in communication if working with international suppliers.

Prioritizing Price Over Quality

While cost-effectiveness is crucial, making purchasing decisions based solely on the lowest price is a common misstep. Cheapest is rarely best when it comes to textiles (Clothing Supplier). Low-quality fabrics can lead to:

- Product returns: Dissatisfied customers due to poor garment performance or durability.

- Reputational damage: Affecting your brand’s standing in the market.

- Production inefficiencies: Fabrics that fray easily, stretch unevenly, or are difficult to work with can increase manufacturing time and waste.

Always balance cost with the quality required for your product’s performance and brand image, especially for functional fabrics like anti-sweat materials where performance is key.

Neglecting Lead Times and Production Schedules

Underestimating lead times for production and shipping can cause significant delays in your product launch. Always factor in:

- Sample lead times: For development and approval.

- Production lead times: The time it takes for the factory to produce your bulk order.

- Shipping time: Depending on the shipping method (air vs. sea) and origin.

- Buffer time: Account for unforeseen delays like customs clearance or production issues.

Accurate timeline planning is crucial for timely product delivery and customer satisfaction.

Building Long-Term Relationships with Your Fabric Suppliers

Establishing strong, enduring relationships with your fabric suppliers is a strategic asset for any small business. Beyond transactional benefits, fostering trust and consistent communication can lead to a more resilient and supportive supply chain.

Benefits of Long-Term Partnerships

- Better Pricing and Terms: Loyal customers often receive preferential pricing, volume discounts, or more flexible payment terms over time.

- Priority Service: In times of high demand or unforeseen challenges, suppliers may prioritize orders from trusted, long-standing clients.

- Reliable Supply Chain: A consistent relationship ensures a more stable and predictable flow of materials, minimizing disruptions.

- Access to New Materials and Innovation: Suppliers are more likely to share insights into new fabric developments, trends, or offer custom solutions to their key partners (MakeMine).

- Problem-Solving Support: When issues arise (e.g., quality concerns, shipping delays), a strong relationship facilitates quicker and more cooperative resolutions.

Strategies for Cultivating Strong Relationships

- Clear and Consistent Communication: Maintain open lines of communication, providing detailed specifications and prompt feedback. Be responsive to their inquiries.

- Prompt Payments: Adhering to agreed-upon payment schedules builds trust and reinforces your reliability as a client.

- Provide Constructive Feedback: Share insights on fabric performance or market needs in a constructive manner, helping suppliers improve their offerings.

- Be Reasonable and Realistic: Understand that unforeseen circumstances can occur. Approach challenges with a problem-solving mindset rather than an accusatory one.

- Mutual Respect: Treat your suppliers as valued partners in your business’s success. Recognize their expertise and the effort they put into fulfilling your orders (Forbes).

By investing in these relationships, you not only secure a consistent and high-quality supply of materials but also gain a valuable partner who can contribute to your business’s growth and innovation.

Conclusion: Empowering Your Business with the Right Wholesale Fabric Materials

Navigating the landscape of wholesale fabric materials sourcing can initially seem daunting for new small businesses. However, by adopting a structured approach and adhering to the principles outlined in this guide, entrepreneurs can confidently acquire the materials necessary to bring their visions to life. From meticulously defining your fabric needs and identifying reputable suppliers to asking the right questions and streamlining the procurement process, each step contributes to building a robust and efficient supply chain.

Avoiding common pitfalls through diligent sample checks, realistic MOQ planning, and clear communication is crucial for mitigating risks and ensuring product integrity. Ultimately, the strategic choice of fabrics is paramount for running a successful business, as it impacts not only costs but also relationships with suppliers and, most importantly, customer satisfaction (Fabriclore). By fostering strong, long-term relationships with your suppliers, you unlock benefits that extend far beyond mere transactions, securing reliable supply, preferential terms, and invaluable industry insights.

The journey of sourcing wholesale fabric materials is more than a logistical challenge; it is a foundational element of your brand’s identity and product quality. Each fabric choice reflects your commitment to excellence and directly influences your market positioning. Equipped with this comprehensive knowledge, you are now empowered to make informed, strategic purchasing decisions, confidently sourcing the right fabrics that will drive your small business towards sustained success and differentiation in a competitive market.

Sources

- The Advantages Of Buying Wholesale Fabric – Spandex Warehouse: https://spandexwarehouse.com/blog/the-advantages-of-buying-wholesale-fabric/

- Wholesale Fabric for Small Business Buy Bulk – Source of Fabric: https://www.sourceoffabric.com/how-to-buy-fabric-wholesale-best-places/

- A Beginners Guide to Fabric Types – Hawthorn Intl: https://www.hawthornintl.com/fabric-guide

- The Ultimate Guide to Different Fabric Types – Fabric Mill: https://www.fabricmill.com/blog/post/different-fabric-types-guide?srsltid=AfmBOoo6pQFpwJeT3kXT0ClUKGhrX9pnyGnOE9VGgVQj4_Ik4hOJp9_2

- How to Buy Fabric Wholesale? Best Places for Bulk Purchase – Source of Fabric: https://www.sourceoffabric.com/how-to-buy-fabric-wholesale-best-places/

- An Ultimate Guide to Fabric Sourcing – Sinosilk: https://sino-silk.com/fabric-sourcing/

- Top 30 Questions To Ask Wholesale Clothing Manufacturers – MakersRow: https://makersrow.com/blog/wholesale-clothing-manufacturers/

- Fabric Sourcing — Process Explained + Examples – Procurement Tactics: https://procurementtactics.com/fabric-sourcing/

- The Ultimate Guide to Fabric Sourcing for Your Clothing Line in 2025 – Makemine: https://www.makemine.com/blog/fabric-sourcing

- How to Avoid Mistakes When Purchasing Wholesale Fabrics Online – Spandex Warehouse: https://spandexwarehouse.com/blog/how-to-avoid-mistakes-when-purchasing-wholesale-fabrics-online/

- 5 Common Mistakes to Avoid When Buying Wholesale Clothing – Clothing Supplier: https://www.clothingsupplier.com/blogs/news/5-common-mistakes-to-avoid-when-buying-wholesale-clothing?srsltid=AfmBOooIuTPR8UdbQsluOzoSir4CJLZxqHmEF0KUJdx5IzhA4g3EhxLZ

- 6 Ways To Manufacture Long-Lasting Relationships With … – Forbes: https://www.forbes.com/sites/yec/2018/06/05/6-ways-to-manufacture-long-lasting-relationships-with-manufacturers/

- Where Do Small, Medium and Large Businesses Source Their Fabric? – Fabriclore: https://fabriclore.com/blogs/fashion-business-lifestyle-trends/where-do-small-medium-large-businesses-source-fabric?srsltid=AfmBOopD1aPF4tx9CEfv8JEEGfXimb0ta2Km0ZWsqv9Mx-XavdEtawCu

Get Factory Direct Wholesale Price From Us Now

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)