Abstract

Sourcing high-quality materials while adhering to strict budget constraints is a perennial challenge for businesses in the apparel and textile industries. This article aims to provide a comprehensive guide on how to identify and acquire affordable wholesale fabric materials without compromising on the essential attributes of quality and performance. It addresses the core concerns of budget-conscious buyers, offering actionable insights into supplier selection, material evaluation, and strategic purchasing to ensure optimal value for money.

Table of Contents

- The Quest for Affordable Wholesale Fabric Materials: Quality vs. Cost

- Key Channels to Source Cost-Effective Wholesale Fabric Materials

- Evaluating Quality in Budget-Friendly Wholesale Fabric Materials

- Finding Value in Wholesale Anti-Sweat and Garment Fabric Materials

- Advanced Tips for Maximizing Savings on Wholesale Fabric Material Purchases

- Choosing the Right Partner for Your Wholesale Fabric Material Needs

- Achieving the Perfect Balance: Quality and Affordability in Wholesale Fabric Materials

The Quest for Affordable Wholesale Fabric Materials: Quality vs. Cost

Businesses across various sectors, particularly those in fashion, home goods, and industrial applications, frequently encounter the delicate balance between securing cost-effective wholesale fabric materials and ensuring the end product meets desired quality standards. The temptation to opt for the cheapest available materials can be strong, especially when navigating tight budgets. However, this often leads to compromised durability, poor performance, and ultimately, dissatisfaction among customers.

Prioritizing quality is paramount because it directly impacts customer perception and long-term brand reputation. High-quality fabric not only contributes to a superior end product but also makes a lasting impression on consumers, fostering loyalty and repeat business (Search For Fabric). While bulk purchasing can offer significant cost advantages, it is crucial to select materials that will endure, emphasizing the principle of “quality over quantity” (CanvasEtc). The challenge, therefore, lies in meticulously identifying suppliers and materials that offer an optimal balance, ensuring that cost savings do not inadvertently diminish the value or integrity of the final product. This section sets the stage for exploring practical strategies to achieve this crucial equilibrium.

Key Channels to Source Cost-Effective Wholesale Fabric Materials

Identifying reliable and cost-effective channels for sourcing wholesale fabric materials is fundamental to achieving significant savings without sacrificing quality. Businesses have several primary avenues to explore, each offering distinct advantages in terms of pricing, variety, and accessibility.

Direct from Manufacturers

Purchasing directly from fabric manufacturers often yields the lowest prices per yard, as it eliminates intermediaries and their associated markups. Manufacturers typically offer substantial discounts for bulk orders, making this an ideal option for large-scale operations with high volume requirements. This channel also provides opportunities for custom fabric development, allowing businesses to create unique materials tailored to their specific needs. However, direct manufacturer purchases usually come with higher minimum order quantities (MOQs) and longer lead times, requiring careful planning and inventory management.

Wholesale Distributors

Wholesale distributors serve as intermediaries between manufacturers and smaller businesses. They typically stock a wide array of fabrics from multiple mills, offering greater variety and lower MOQs than direct manufacturer purchases. While prices may be slightly higher than direct factory rates, the convenience, reduced lead times, and ability to purchase smaller quantities make distributors an attractive option for many businesses. Many distributors also provide value-added services such as cutting and finishing. Cost savings are a significant advantage when buying fabrics wholesale, as manufacturers and distributors generally offer more competitive pricing compared to retail outlets (Source of Fabric).

Online Wholesale Marketplaces and Directories

The digital landscape has expanded sourcing options significantly. Online wholesale marketplaces and specialized fabric directories connect buyers with a vast network of suppliers from around the globe. These platforms facilitate price comparison, offer diverse product ranges, and can be particularly beneficial for discovering niche fabrics or international suppliers. Building relationships with reliable suppliers is a key outcome of effective fabric sourcing, which these platforms can help initiate (Sino-Silk). While convenient, buyers must exercise due diligence to verify supplier credibility and material quality when using these platforms.

Evaluating Quality in Budget-Friendly Wholesale Fabric Materials

Sourcing affordable wholesale fabric materials does not necessitate a compromise on quality. A proactive approach is essential for locating budget-friendly materials that meet rigorous standards (Ningbo MH). Evaluating fabric quality requires a discerning eye and a systematic approach. Below are practical criteria and tips for assessing the integrity and performance of fabrics, ensuring that cost savings do not undermine the final product’s value.

Visual Inspection

Weave Consistency: Examine the fabric closely for uniform weave patterns. Irregularities, loose threads, or skipped stitches can indicate poor quality and potential weakness.

Color Uniformity: Check for consistent color distribution across the entire bolt. Uneven dyeing or fading spots suggest lower quality.

Defects: Look for snags, holes, stains, or other visible flaws. Even minor defects can render large sections of fabric unusable, negating any cost savings.

Tactile Assessment

Texture: Feel the fabric’s texture. Does it match the expected hand for the fiber type? A rough or overly stiff feel for a supposed soft fabric might indicate inferior processing or fiber content.

Weight and Drape: Assess the fabric’s weight and how it drapes. A fabric that feels too light or lacks proper drape for its intended use may not perform as expected.

Density: A denser weave generally suggests higher quality and durability.

Performance Tests (Preliminary)

Elasticity/Recovery: Gently stretch the fabric to check for elasticity and how well it recovers its original shape. Poor recovery indicates low-quality fibers or construction (The Fabric Mill).

Transparency: Hold the fabric up to the light. Excessive sheerness for a non-sheer fabric can indicate a loose weave or insufficient fiber content, affecting durability and opacity (The Fabric Mill).

Wrinkle Resistance: Crumple a small section of fabric in your hand. How quickly and completely it springs back can give an indication of its wrinkle resistance and recovery properties.

Table: Key Quality Evaluation Parameters for Wholesale Fabric Materials

| Parameter | Description | Indicator of Quality |

|---|---|---|

| Weave Consistency | Uniformity of threads and pattern | Even, tight, no skipped stitches |

| Color Fastness | Resistance to fading or bleeding | Vibrant, consistent color throughout |

| Hand (Texture) | Feel of the fabric against the skin | Smooth, soft, consistent texture |

| Drape | How the fabric hangs or falls | Fluid, graceful, appropriate for material type |

| Durability | Resistance to wear, tear, and pilling | Strong fibers, tight weave, good recovery |

| Dimensional Stability | Resistance to shrinking or stretching | Maintains original size and shape after washing |

![[JuncoSports]The Right Way To Find Reliable Fabric Suppliers That Suits Your Business](https://materials.juncosports.com/wp-content/uploads/2025/07/image-3.jpg)

Finding Value in Wholesale Anti-Sweat and Garment Fabric Materials

Sourcing specialized materials like wholesale anti-sweat fabric and general garment fabric requires specific strategies to ensure both performance and cost-effectiveness. These materials often have unique properties that demand careful consideration beyond basic textile evaluations.

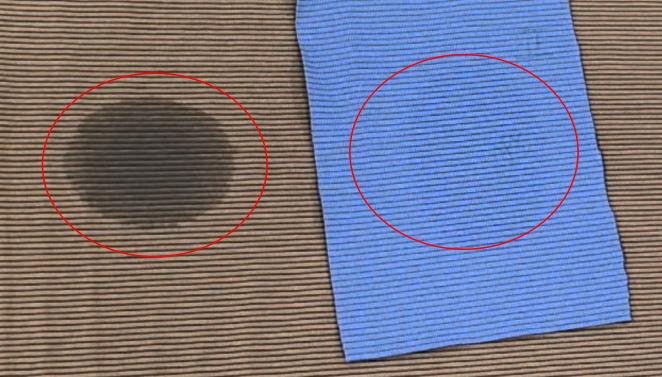

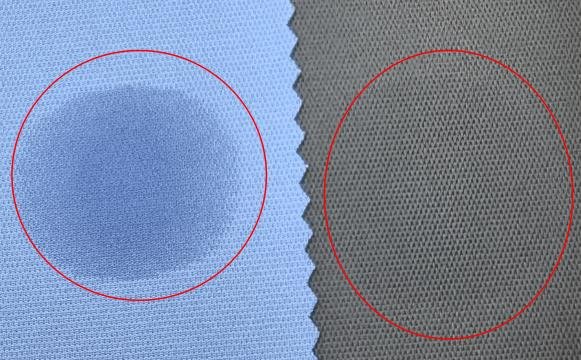

For wholesale anti-sweat fabric, the primary concern is its moisture-wicking and quick-drying capabilities. When evaluating these materials, it is crucial to request detailed performance specifications from suppliers, including moisture absorption rates, drying times, and breathability ratings. While the initial cost might seem higher than conventional fabrics, the added value in terms of wearer comfort and functionality often justifies the investment, especially for activewear, sportswear, or work uniforms where performance is critical. Seeking out suppliers who specialize in technical textiles can provide access to advanced materials and expert advice.

For general garment fabric, finding value involves a broader scope, encompassing aesthetics, hand-feel, durability, and suitability for the intended apparel line. It is advisable to visit fabric vendors and explore the available options firsthand (Fashion Brain Academy). This direct interaction allows for tactile evaluation and understanding of different material properties. When purchasing any cloth material for garments, it is essential to consider the minimum order quantities (MOQs) offered by vendors to ensure they align with your brand’s production scale (Fashion Brain Academy).

Regardless of the specific fabric type, finding reliable partners is crucial. This often involves researching textile wholesalers online and checking reputable wholesale clothing directories to identify potential suppliers (Trendsi). Engaging with suppliers who understand the specific requirements for performance fabrics or a particular garment type can lead to better value and more successful product development. Always request samples to conduct thorough in-house testing before committing to large bulk purchases, especially for specialized fabrics where performance claims need validation.

Advanced Tips for Maximizing Savings on Wholesale Fabric Material Purchases

Beyond initial price comparison, several strategic approaches can significantly reduce the overall cost of acquiring wholesale fabric materials. These advanced tips focus on leveraging purchasing power, optimizing logistics, and building strong supplier relationships.

Leverage Bulk Purchasing Advantages

The most straightforward method for cost reduction is increasing order volume. Suppliers often offer tiered pricing structures, with substantial discounts for larger quantities. The economic benefits of purchasing fabric in bulk are significant, including reduced costs, increased scalability for production, and a more reliable material supply (New Star Fabric). Analyze your historical consumption data and future projections to determine the optimal bulk purchase quantity that balances savings with inventory holding costs.

Negotiation Tactics

Always be prepared to negotiate prices, especially for large orders or long-term commitments. Research market rates to substantiate your offers. Factors that can strengthen your negotiation position include:

Commitment to Volume: Offer consistent, large orders over time.

Early Payment Terms: Propose favorable payment terms, such as upfront payment or net 15 days, in exchange for a discount.

Long-term Contracts: Secure better rates by committing to an annual supply agreement.

Supplier Loyalty: Highlight your history as a reliable customer.

Understand Minimum Order Quantities (MOQs)

While MOQs can be a barrier for smaller businesses, understanding how to manage them is crucial for savings.

Combine Orders: If possible, group different fabric needs into one larger order to meet MOQs.

Negotiate MOQs: Some suppliers may be flexible, especially if you have a promising growth trajectory or if the fabric is a slow-moving item for them.

Consider Stock Lots/Overruns: These are often available at a steep discount, though quantities and patterns may be limited.

Optimize Shipping and Logistics

Shipping costs can significantly inflate the total price of wholesale fabric materials.

Evaluate Shipping Options: Compare various freight carriers and methods (air, sea, land) based on your timeline and budget (Source of Fabric).

Local Suppliers/Pickup: For local suppliers, consider picking up the fabric yourself to eliminate delivery charges (Source of Fabric).

Consolidate Shipments: If buying from multiple suppliers in the same region, explore freight consolidation services.

Payment Terms and Discounts

Beyond price, explore the possibility of discounts for early payment or favorable credit terms. Building a strong credit history with suppliers can open doors to more flexible payment options and potentially better pricing in the future.

Choosing the Right Partner for Your Wholesale Fabric Material Needs

Selecting a long-term supplier for your wholesale fabric materials is a strategic decision that extends beyond mere price comparison. A reliable and compatible partner can streamline your supply chain, ensure consistent quality, and support your business growth. Several essential factors should be meticulously evaluated when making this choice.

Reliability and Consistency

A supplier’s ability to consistently deliver materials on time and to the agreed-upon specifications is paramount. Assess their track record for meeting deadlines and handling unforeseen issues. Inquire about their production capacity and contingency plans. Reliability is a key factor to assess when choosing a supplier that meets your needs (Source of Fabric).

Quality Assurance and Compliance

Verify the supplier’s quality control processes. Do they conduct rigorous inspections? Do their fabrics meet international quality standards and certifications relevant to your industry (e.g., Oeko-Tex, GOTS, ISO)? Transparency regarding their fabric sourcing is also important (World Linen).

Customer Service and Communication

Effective communication is vital for a smooth partnership. Evaluate their responsiveness, willingness to address concerns, and ability to provide clear and timely updates. A supplier who understands your specific needs and can offer tailored solutions is invaluable.

Pricing Structure and Flexibility

While price isn’t the sole determinant, it remains a critical factor. Compare pricing across multiple suppliers for similar quality and volume. Discuss their pricing models, potential for bulk discounts, and flexibility in payment terms.

Minimum Order Quantities (MOQs)

Ensure the supplier’s MOQs align with your current and projected production volumes. Some suppliers offer lower MOQs for new clients or for specific fabric types, while others cater exclusively to large-scale buyers.

Customization and Innovation Capabilities

If your business requires unique fabric designs, finishes, or blends, assess the supplier’s capacity for customization. A partner who can innovate and adapt to evolving market trends can provide a competitive edge.

Ethical and Sustainable Practices

Increasingly, consumers and businesses prioritize ethical sourcing and sustainable manufacturing. Inquire about the supplier’s environmental policies, labor practices, and adherence to social responsibility standards.

Location and Logistics

Consider the supplier’s geographical location relative to your manufacturing or distribution points. Proximity can reduce shipping costs and lead times, while international suppliers may offer unique fabrics but require more complex logistics planning. World Linen emphasizes that “location matters” and to “make sure your timeline can be met” when choosing a distributor (World Linen).

Achieving the Perfect Balance: Quality and Affordability in Wholesale Fabric Materials

Successfully sourcing affordable, high-quality wholesale fabric materials is not merely a cost-cutting exercise; it is a strategic imperative that underpins product integrity and business profitability. The journey involves a diligent combination of informed decision-making, meticulous evaluation, and a forward-thinking approach to supplier relationships.

Key strategies for achieving this critical balance include:

Thorough Research: Invest time in exploring various sourcing channels, from direct manufacturers to online marketplaces, to gain a comprehensive understanding of market prices and available options.

Rigorous Quality Assessment: Never compromise on the evaluation of cloth material quality. Implement systematic checks, including visual, tactile, and preliminary performance tests, to ensure that cost-effective materials still meet stringent standards.

Strategic Sourcing for Specialized Fabrics: For materials like wholesale anti-sweat fabric or specialized garment fabric, prioritize functionality and performance specifications alongside price. Identifying niche suppliers for these specific needs can lead to better value.

Maximizing Savings Strategically: Employ advanced tips such as leveraging bulk purchasing power, mastering negotiation tactics, and optimizing logistics to drive down costs without devaluing the product. Always account for potential hidden costs when calculating the total cost of ownership (Fabriclore).

Cultivating Strong Supplier Partnerships: Recognize that a supplier is more than just a vendor; they are a partner in your supply chain. Choose partners based on reliability, communication, quality consistency, and shared values, fostering long-term relationships that can yield ongoing benefits and support.

By integrating these strategies, businesses can navigate the complexities of the fabric market, secure materials that look good, last longer, and are affordable (Fabriclore), ultimately empowering them to create high-value products that resonate with discerning consumers.

Conclusion

The pursuit of affordable wholesale fabric materials without compromising quality is a tangible and achievable goal for businesses committed to strategic sourcing. By adopting a multi-faceted approach that combines diligent research, rigorous material evaluation, astute negotiation, and the cultivation of strong supplier relationships, organizations can optimize their procurement processes. This ensures not only immediate cost savings but also contributes to the long-term integrity of their products and the sustainability of their operations, affirming that value need not be sacrificed for economic efficiency.

Sources

Looking For Textile Supplier? Get Wholesale Price From Us Now

![[JuncoMaterials]The Ultimate Guide to Finding a Fabric Supplier for Your New Clothing Brand](https://materials.juncosports.com/wp-content/uploads/2025/07/image-13.jpg)

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)