When sourcing fabrics for clothing, activewear, or home textiles, quality determines everything — from the look and feel of your products to customer satisfaction and brand reputation. For buyers who can’t touch or see the fabric in person, evaluating quality becomes a skill that goes far beyond visuals. With the right approach, you can identify reliable materials, avoid production risks, and ensure your final products meet the highest standards.

Understanding the Basics of Fabric Quality

Fabric quality is a balance between several elements — comfort, durability, color retention, and suitability for purpose. High-quality fabric should not only feel soft or strong; it should also behave consistently throughout cutting, sewing, and washing.

For instance, fabrics made for yoga wear need to be stretchy, moisture-wicking, and breathable, while fabrics for T-shirts should focus on softness and comfort. The first step to assessing quality is understanding the specifications your supplier provides — details like GSM (grams per square meter), fiber composition, yarn density, weave or knit structure, and finishing process. Each factor tells a story about how the fabric will perform over time.

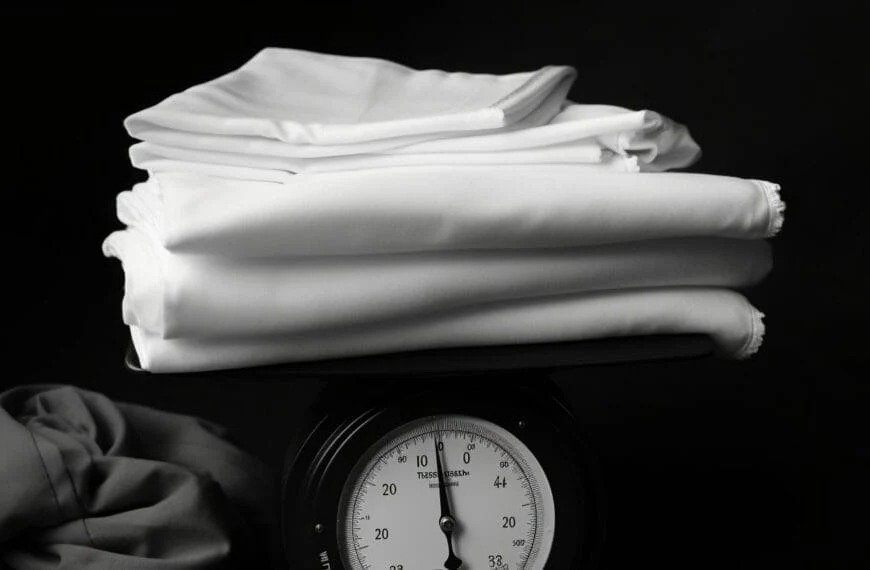

GSM and Weight: What It Tells You

GSM stands for “grams per square meter,” which indicates the weight and density of the fabric. It’s one of the easiest ways to compare materials remotely.

Light fabrics, around 120–150 GSM, are ideal for T-shirts and summer tops. Medium-weight fabrics, 160–220 GSM, are often used for polo shirts or leggings, while heavier fabrics above 250 GSM are suitable for hoodies and winterwear.

However, a heavier fabric doesn’t automatically mean better quality. The yarn type, weave tightness, and finishing treatment all influence how the material feels and performs. A low-GSM cotton jersey can feel luxurious if it’s made with long-staple fibers and well-balanced tension. Meanwhile, a high-GSM polyester may feel coarse if it lacks good finishing. Always read GSM data in context with fiber and finish information.

Fiber Composition and Its Role in Quality

The fabric’s composition defines its comfort, durability, and functionality. Natural fibers like cotton, bamboo, and linen offer softness and breathability, while synthetic fibers such as polyester, nylon, and spandex bring elasticity, strength, and moisture control.

For activewear or yoga leggings, blends like nylon + spandex or polyester + spandex work well because they combine stretch with quick-drying ability. For everyday tees, cotton-rich blends ensure comfort, while cotton-poly fabrics add wrinkle resistance and shape retention.

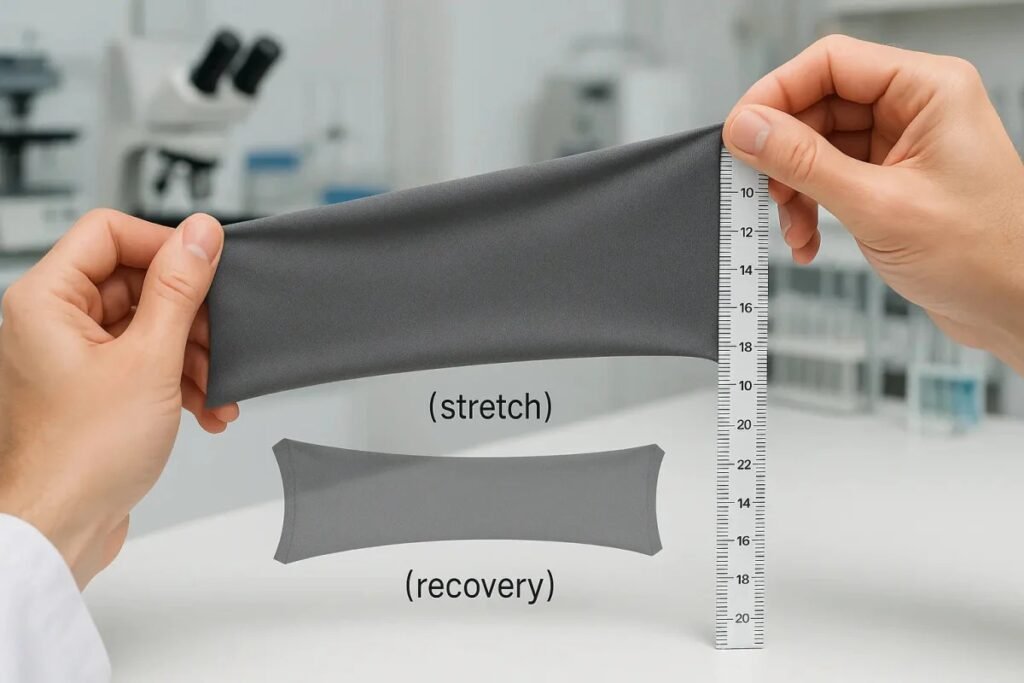

Buyers should confirm the fiber ratio with suppliers. A difference of even 5% in composition can change fabric performance. The label might say “85% polyester + 15% spandex,” but if the spandex content drops to 10%, the stretch and recovery will be noticeably weaker. Reliable suppliers will provide exact fiber breakdowns verified by lab tests or specification sheets.

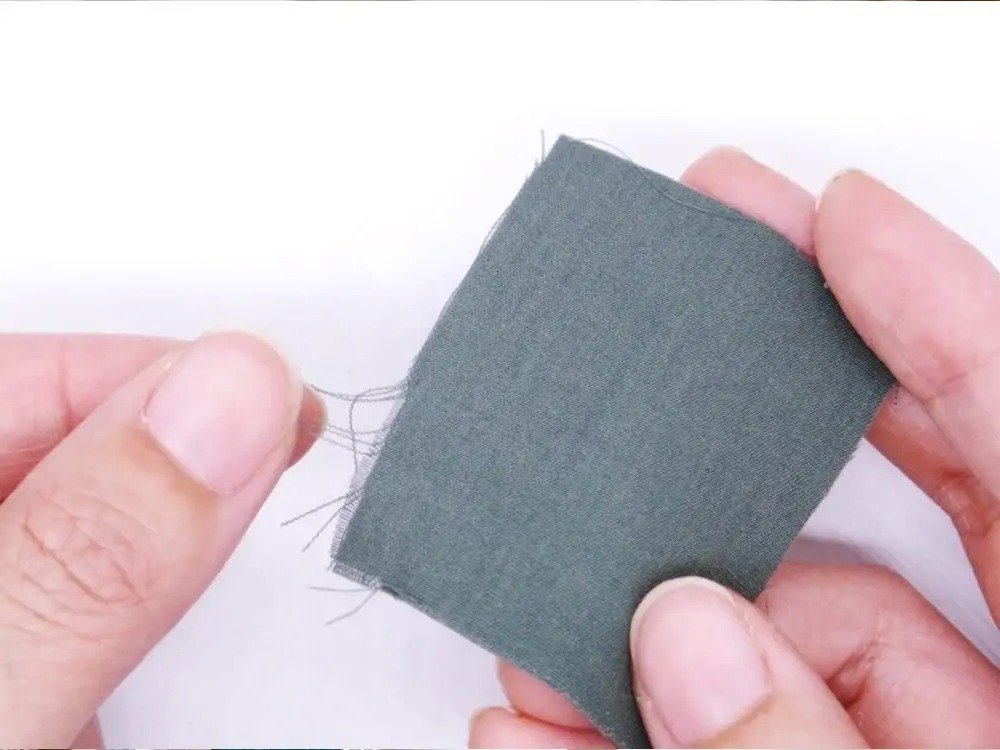

How to Visually Evaluate Fabric Samples

When physical samples or swatches are available, a careful visual check can reveal much about quality. Here’s how to conduct a simple but effective evaluation:

- Surface texture: Look for evenness — no loose yarns, fuzz, or rough patches.

- Color consistency: Compare across light and dark areas to detect uneven dyeing.

- Elastic recovery: Stretch and release the fabric; good-quality spandex blends should return smoothly without wrinkles.

- Transparency: Hold it up to light — lightweight fabrics shouldn’t be excessively see-through unless intended for layering.

- Wrinkle test: Squeeze the fabric firmly; if deep wrinkles remain, it may lack elasticity or proper finishing.

These small checks can save you from larger production issues later. If anything feels off, request another batch of samples or a different dye lot before confirming your order.

Performance and Durability Testing

When working with large-scale production, relying only on look and feel is risky. That’s why performance testing is a crucial step. Reliable suppliers often provide reports that follow ISO, AATCC, or ASTM standards.

Below is a quick overview of common tests and their meanings:

| Test Type | Purpose | Ideal Result for Quality Fabric |

|---|---|---|

| Colorfastness | Checks color retention after washing | Grade 4–5 |

| Shrinkage | Measures dimensional stability | ≤3% |

| Pilling Resistance | Tests surface durability | Grade 4 or higher |

| Stretch Recovery | Measures elasticity and rebound | Recovers 90–95% |

| Tensile Strength | Tests breaking resistance | High stability |

When you compare suppliers, ask if they can share recent test results. A trustworthy manufacturer won’t hesitate to show certified reports or even conduct a custom test for your order.

Communication and Supplier Transparency

In online B2B transactions, the communication between buyer and supplier can make or break product quality. A good supplier should be transparent, detailed, and proactive.

Before you finalize an order, make sure you confirm:

- The exact GSM and composition of your selected fabric.

- The finishing process — whether it includes anti-pilling, quick-dry, or UV protection.

- The tolerance for GSM and color difference in bulk.

- The testing reports or certifications provided.

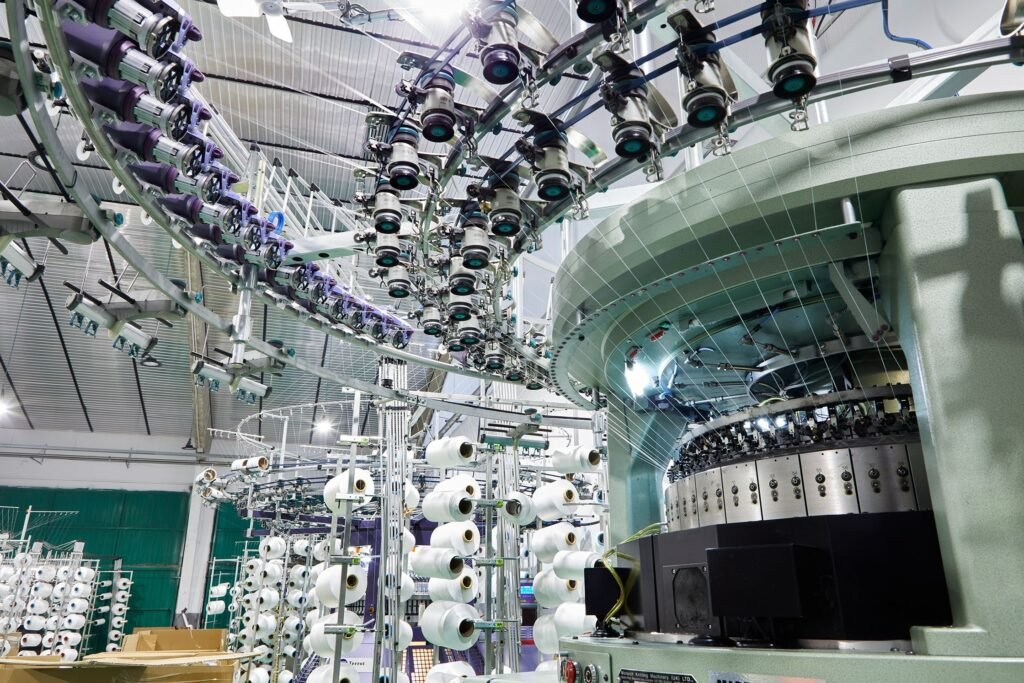

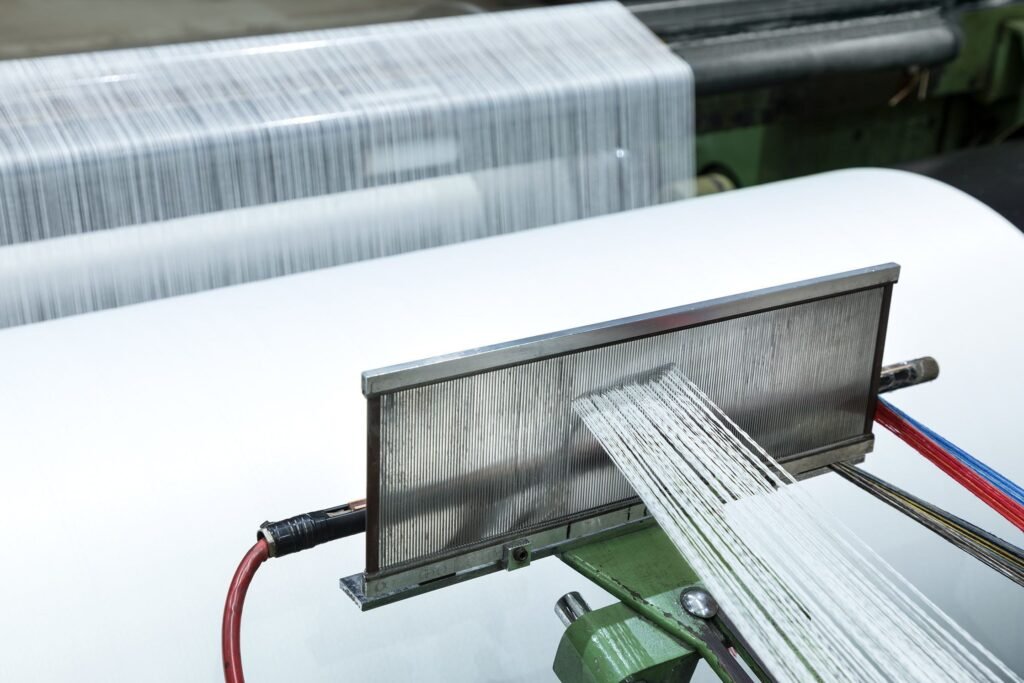

Suppliers who are confident in their production quality often offer detailed data sheets, factory photos, or videos showing the material’s texture and stretch. This helps buyers make confident decisions even from afar.

How to Use GSM and Testing Data When Negotiating Orders

For B2B buyers, data is power. Understanding GSM, fiber structure, and test results allows you to negotiate price and quality more effectively.

- If two suppliers quote the same fabric name but one offers a lower GSM, it could indicate thinner yarn or looser knitting — both of which may affect durability.

- A supplier with certified pilling resistance or colorfastness results can justify a slightly higher price, especially for premium apparel lines.

- During long-term cooperation, keeping GSM and test records helps ensure future orders remain consistent in feel and performance.

By using these objective indicators, buyers can move beyond subjective impressions and base their sourcing decisions on measurable quality.

Final Tips for Confident Fabric Orders

Checking fabric quality before placing a bulk order is not just about technical data — it’s also about experience and communication. Here are a few final guidelines:

- Always request swatches or small yardage before mass production.

- Compare multiple suppliers using the same parameters: GSM, color, and fiber content.

- Keep all test reports and approved samples as future references.

- If possible, start with smaller trial orders to evaluate real-world performance.

Taking these steps builds trust between buyer and supplier and ensures stable production for future projects. In the long run, this approach saves both time and cost by reducing returns, disputes, and inconsistent results.

Conclusion

Fabric quality determines how your products look, feel, and last. Before placing an order, evaluating GSM, fiber composition, finishing, and testing data helps you make informed decisions. With clear communication, reliable sampling, and verified testing, you can confidently source high-quality materials that align with your brand’s standards.

Whether you’re creating yoga wear, T-shirts, or sustainable apparel, investing time in checking fabric quality always pays off. It ensures better consistency, stronger brand reputation, and satisfied end customers — the ultimate goal for every professional in the textile industry.

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)