Abstract

For a startup clothing brand, securing a reliable and high-quality clothing material supplier is paramount to success. The burgeoning textile industry in China offers a vast array of options, but navigating this landscape requires meticulous due diligence. This article provides a comprehensive checklist for vetting a Chinese fabric supplier, covering everything from initial identification to long-term partnership building. By understanding the critical steps involved in assessing quality, verifying reliability, and managing logistics, startup brands can mitigate risks, ensure consistent product standards, and build a resilient supply chain.

Table of Contents

- Why Vetting Your Chinese Clothing Material Supplier is Non-Negotiable for Startup Brands

- Step One: Identifying Potential Clothing Material Suppliers from China

- Evaluating Fabric Quality & Production Capabilities: A Deep Dive into Materials

- Beyond Samples: Verifying the Clothing Material Supplier’s Reliability and Reputation

- Navigating Quotations, Payment Terms, and MOQs with Chinese Suppliers

- Ensuring Smooth Logistics and Post-Production Quality Control for Overseas Shipments

- Common Red Flags and Pitfalls When Partnering with an Overseas Clothing Material Supplier

- Building a Lasting Partnership: From First Order to Long-Term Collaboration

Why Vetting Your Chinese Clothing Material Supplier is Non-Negotiable for Startup Brands

For any startup clothing brand, the choice of a clothing material supplier is a foundational decision that directly impacts product quality, production timelines, and ultimately, brand reputation. The textile manufacturing landscape in China, while offering competitive pricing and vast production capacity, also presents unique challenges. Without a rigorous vetting process, new brands risk facing issues such as inconsistent quality, production delays, communication breakdowns, and even financial losses due to unreliable partners. As highlighted by industry experts, thorough evaluation of every potential supplier, accompanied by clear communication, document verification, and sample inspection, is simply non-negotiable for success (Modaknits Apparel). Overlooking this critical step can lead to significant setbacks, particularly for a burgeoning brand with limited resources and reputation to protect. Therefore, investing time in a comprehensive vetting process is not merely a formality but a strategic imperative to ensure a reliable and sustainable foundation for your brand.

Step One: Identifying Potential Clothing Material Suppliers from China

The initial phase of securing a Chinese clothing material supplier involves strategic research and identification of potential candidates. This crucial first step lays the groundwork for all subsequent vetting processes. A primary method involves leveraging online B2B platforms such as Alibaba, Made-in-China, and Global Sources. These platforms host thousands of suppliers, often with detailed profiles, product catalogs, and customer reviews. While convenient, it is essential to remember that these platforms serve as starting points and require further verification. Additionally, attending international trade shows, such as the Canton Fair in Guangzhou or Intertextile Shanghai Apparel Fabrics, provides an invaluable opportunity to meet suppliers face-to-face, inspect samples, and discuss capabilities directly. This personal interaction can offer insights not available through online channels, helping to evaluate supplier credibility (Yilities). For brands seeking more tailored options or lacking the time for extensive research, hiring a local sourcing agent in China can be an effective strategy. These agents possess localized knowledge, language skills, and established networks, streamlining the initial identification and preliminary vetting stages (Thesynerg). Regardless of the method, the goal is to compile a diverse list of potential suppliers that align with your brand’s specific needs, including fabric types, quality standards, and production volumes.

Evaluating Fabric Quality & Production Capabilities: A Deep Dive into Materials

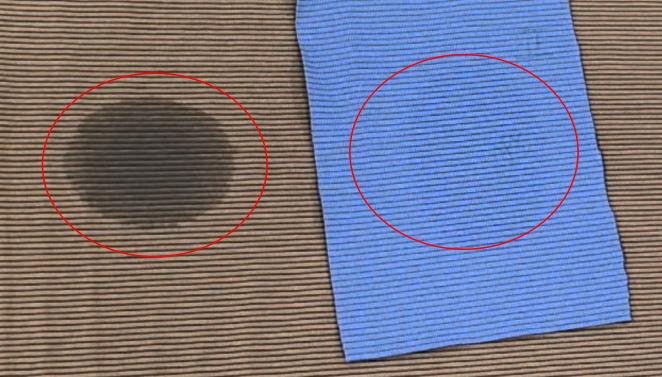

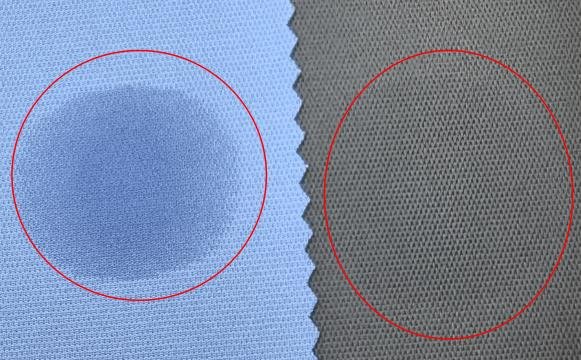

Once potential suppliers are identified, a rigorous evaluation of their fabric quality and production capabilities becomes imperative. This phase is fundamental to ensuring your brand’s garments meet desired standards and consumer expectations. It begins with requesting samples of the specific cloth material you intend to use. When evaluating samples, assess various properties such as hand-feel, drape, color consistency, and overall appearance. For specialized items like activewear, evaluate performance attributes, perhaps even requesting samples of wholesale anti-sweat fabric or sweat fabric. Visual inspection should be complemented by physical testing to ascertain durability, colorfastness, shrinkage, pilling resistance, and tensile strength. These tests can be conducted by independent third-party laboratories to ensure unbiased results, as physical testing of textiles is crucial for quality assurance (QTRLLab). Furthermore, inquire about relevant certifications (e.g., OEKO-TEX Standard 100 for harmful substances, GOTS for organic textiles, or GRS for recycled content), which indicate a commitment to quality and ethical manufacturing practices. Beyond material assessment, verify the supplier’s production capabilities. This includes understanding their factory’s capacity, machinery, and technical expertise to handle your specific order volume and fabric requirements. A supplier capable of consistently producing high-quality garment fabric at scale is crucial for long-term growth. Consider the following checklist when evaluating materials and capabilities:

| Evaluation Aspect | Key Considerations | Verification Method |

|---|---|---|

| Fabric Quality | Hand-feel, drape, color consistency, structural integrity, appearance. | Sample review, physical touch, visual inspection. |

| Performance Testing | Colorfastness, shrinkage, pilling, tensile strength, moisture-wicking (for specialized fabrics). | Third-party lab testing, internal supplier test reports (with verification). |

| Certifications | OEKO-TEX, GOTS, GRS, bluesign, ISO standards relevant to textiles. | Request valid certificates, verify authenticity with issuing bodies. |

| Raw Material Sourcing | Origin of fibers, ethical and sustainable sourcing practices. | Supplier transparency, documentation. |

| Production Capacity | Ability to meet your MOQ and scaling needs, reliable production lead times. | Discussions, factory visit (if possible), reference checks. |

| Technical Expertise | Experience with specific fabric compositions, finishes, and complex production processes. | Portfolio review, technical Q&A sessions, trial orders. |

Beyond Samples: Verifying the Clothing Material Supplier’s Reliability and Reputation

While material samples offer a tangible assessment of quality, true supplier vetting extends far beyond them to encompass reliability and reputation. This due diligence is crucial for a trustworthy long-term partnership. Begin by verifying their business registration and licenses to ensure they are a legally operating entity in China. Request copies of their business license and check them against official government databases where possible. Customer reviews and testimonials provide valuable insights into a supplier’s consistency in product quality, communication, and delivery. Actively seek out independent reviews on B2B platforms, industry forums, and even through direct references from other brands that have worked with them. Conducting regular audits and inspections, and reviewing customer feedback are effective ways to assess a supplier’s consistency (FasterCapital). For significant orders or long-term partnerships, consider conducting a factory audit, either in-person or via a reputable third-party inspection service. An audit provides a firsthand look at their production facilities, quality control systems, labor practices, and overall operational efficiency. For high-end needs, a Supplier Quality Engineer (SQE) might audit to verify consistent delivery on performance (LinkedIn – Mumsimakhokolo). Finally, assess their communication responsiveness and clarity. A reliable supplier will maintain open, prompt, and professional communication, addressing your queries thoroughly and proactively. This aspect often reflects their commitment to customer service and transparent business practices.

Navigating Quotations, Payment Terms, and MOQs with Chinese Suppliers

Understanding and strategically negotiating financial agreements are vital when dealing with Chinese suppliers. The quotation structure typically involves various Incoterms (International Commercial Terms) like FOB (Free On Board), EXW (Ex Works), or CIF (Cost, Insurance, and Freight), each impacting who bears the costs and risks at different stages of shipment. It’s crucial to compare these terms across multiple suppliers, not just the base price, to get a holistic view of the total cost. Payment terms are another critical negotiation point. Standard practice often involves an upfront deposit (e.g., 30%) and the remaining balance upon shipment or against a Bill of Lading. For larger orders, consider Letters of Credit (LCs) for added security, though these can be more complex and costly. Always ensure payment terms are clearly stipulated in a written contract to avoid future disputes, and compare price, quality, MOQ, lead times, and payment terms across multiple suppliers (Sara PSL Blog). Minimum Order Quantities (MOQs) are a significant consideration, especially for startups. Chinese suppliers often have MOQs to make production cost-effective for them. Understanding and negotiating the MOQ is a critical aspect of doing business, balancing order size and cost (Sino-Shipping). Negotiating MOQs might be possible, particularly for initial trial orders or if your brand demonstrates potential for large future orders. Be prepared to discuss your long-term vision and flexibility. Transparent financial agreements are key to fostering trust and preventing misunderstandings.

Ensuring Smooth Logistics and Post-Production Quality Control for Overseas Shipments

Once your order is complete, the journey from China to your warehouse involves complex logistics and a final critical layer of quality control. Effective planning is paramount for maintaining quality when manufacturing overseas (EWMFG News). This begins with selecting appropriate shipping methods (sea freight for cost-efficiency, air freight for speed) and a reliable freight forwarder who can manage customs clearance, documentation, and transportation. Understanding the chosen Incoterms from the quotation stage will dictate responsibilities for costs, risks, and insurance during transit. A crucial step before shipment is the Pre-Shipment Inspection (PSI). This involves a third-party inspector visiting the factory to check the finished goods against your specifications, ensuring quality standards, quantity accuracy, and proper packaging. This final inspection helps catch any defects before the goods leave the factory, saving considerable time and expense on resolving issues post-arrival. Upon receiving the goods, conduct a thorough incoming quality check. Even with PSI, minor issues can occur during transit. Document any discrepancies immediately and communicate them to your supplier and freight forwarder. Proactive communication and clear processes for handling potential issues during transit are essential for a smooth supply chain and mastering logistics quality control (Number Analytics).

Common Red Flags and Pitfalls When Partnering with an Overseas Clothing Material Supplier

Navigating the complexities of overseas sourcing means being vigilant for potential warning signs that could jeopardize your business. One of the most significant red flags is unusually low pricing that seems too good to be true. While competitive pricing is an advantage of sourcing from China, drastically low quotes compared to other suppliers can indicate compromised quality, hidden costs, or even a scam. Ignoring red flags in supplier contracts can lead to missed deadlines, poor quality, and unexpected costs (Shanghai Garment). Vague or inconsistent communication is another major warning. If a supplier is slow to respond, provides unclear answers, or avoids direct questions, it can be a precursor to future communication breakdowns and misunderstandings. A lack of transparency regarding their factory operations, production processes, or unwillingness to provide third-party audit reports should also raise concerns. Suppliers who insist on unusual payment methods, such as direct transfers to personal accounts or large upfront payments without proper contracts, should be approached with extreme caution, as these are common tactics in fraudulent schemes. Common pitfalls for new brands often include insufficient due diligence, rushing the vetting process, failing to secure detailed written contracts, or not clearly defining quality standards and specifications. Spotting warning signs early and avoiding these common pitfalls in product sourcing is critical (China2West). Diligence and patience are your best allies in mitigating these risks.

Building a Lasting Partnership: From First Order to Long-Term Collaboration

Securing your first successful order with a Chinese fabric supplier is just the beginning of a potentially long and fruitful relationship. Building a lasting partnership goes beyond transactional interactions and fosters mutual growth. Key to this is establishing clear and consistent communication channels. Regular updates, prompt responses to queries, and proactive sharing of information are essential. Provide constructive feedback on every order, whether positive or areas for improvement, to help the supplier understand your needs better and enhance their service. Identifying your goals and values, and then communicating and collaborating effectively, are fundamental to building and maintaining long-term partnerships (LinkedIn – How to Build). View your supplier as a strategic partner rather than just a vendor. Sharing your brand’s vision, future plans, and upcoming product needs can enable them to offer more relevant solutions, new material innovations, or more efficient production strategies. Mutual growth is fostered when both parties are invested in each other’s success. This collaborative approach, starting with a strong foundation and clear objectives, often leads to better pricing, preferential lead times, and a willingness to solve problems together (Sphere Digital Recruitment). By nurturing this relationship, your startup can create a robust and reliable supply chain that supports sustained success and innovation in the competitive fashion industry.

Conclusion

The journey of a startup clothing brand from concept to consumer is significantly influenced by the integrity of its supply chain, with the clothing material supplier at its core. Vetting a Chinese supplier demands a systematic and rigorous approach, encompassing thorough research, detailed quality assessment, stringent reliability checks, and astute financial negotiations. While challenges exist, the rewards of a reliable partnership—consistent quality, timely deliveries, and scalable production—far outweigh the initial investment in due diligence. By proactively identifying potential risks and fostering open communication, brands can transform a mere vendor relationship into a collaborative alliance. This strategic partnership is not merely about procuring materials; it’s about building the backbone of your brand’s reputation and ensuring its long-term viability in a dynamic market.

Sources

Looking For Textile Supplier? Get Wholesale Price From Us Now

![[JuncoMaterials]How to Vet a Clothing Material Supplier from China: A Checklist for Quality and Reliability](https://materials.juncosports.com/wp-content/uploads/2025/08/image-1.jpg)

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)