Abstract

For product developers and designers, understanding the intricacies of anti-sweat fabrics is paramount in today’s performance-driven apparel market. This comprehensive guide serves as an essential resource, delving into the core definitions, scientific principles, diverse types, and crucial selection factors of these innovative materials. It further explores their wide-ranging applications and the significant business advantages they offer. The aim is to equip industry professionals with the knowledge necessary to make informed decisions, ensuring the selection of the most suitable cloth material for their specific apparel lines, from high-performance sportswear to comfortable workwear.

Table of Contents

- Understanding The Core: What Are Anti-Sweat Fabrics?

- The Science Behind Dryness: How Anti-Sweat Technology Works

- Exploring Various Anti-Sweat Fabric Types for Apparel Production

- Key Factors in Selecting The Ideal Anti-Sweat Fabric for Your Line

- Application Spotlight: Where Anti-Sweat Fabrics Excel in Apparel

- The Business Advantage: Why Invest in High-Quality Anti-Sweat Fabrics for Your Brand

- Sourcing Your Anti-Sweat Fabrics: A Wholesale Guide for B2B Buyers

- Elevate Your Apparel: The Future of Comfort with Advanced Anti-Sweat Fabrics

Understanding The Core: What Are Anti-Sweat Fabrics?

At its essence, an anti-sweat fabric refers to a material engineered to manage moisture (sweat) effectively, preventing it from accumulating on the skin and keeping the wearer dry and comfortable. This is distinct from simply “sweat-absorbing” materials. While some fabrics might absorb moisture, true anti-sweat properties involve a more dynamic process of wicking and evaporation. These fabrics are fundamental to modern apparel, enhancing user experience in various demanding environments, from athletic pursuits to daily professional wear. The development of such textiles has revolutionized comfort standards, addressing a primary pain point for consumers: the discomfort of damp clothing. It is worth noting that many traditional “sweat-resistant” or “moisture-wicking” fabrics are synthetic, and some may rely on chemical treatments that can degrade over time with washing (Thompson Tee). Beyond just managing moisture, some advanced fabrics also incorporate anti-odor technologies, which work by targeting the bacteria on the skin that cause body odor (Neat Apparel). This multi-functional approach underscores their importance in today’s market.

The Science Behind Dryness: How Anti-Sweat Technology Works

The effectiveness of anti-sweat fabrics hinges on three primary mechanisms: moisture-wicking, quick-drying, and breathability. These properties work in concert to facilitate the body’s natural cooling process.

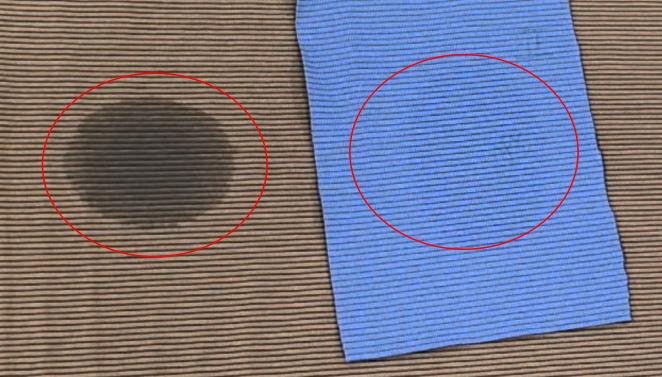

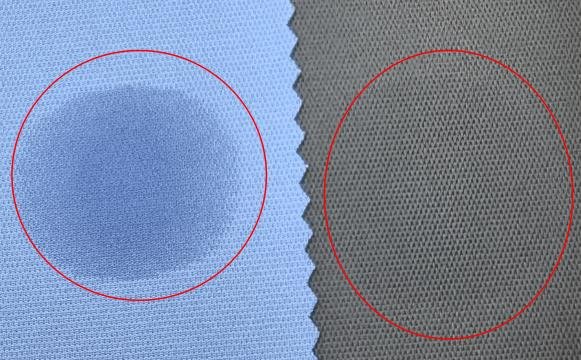

Moisture-Wicking: This is the cornerstone of anti-sweat technology. Moisture-wicking fabrics are engineered with unique fibers and weave structures that utilize capillary action. This process draws moisture (sweat) away from the skin and transfers it to the outer surface of the fabric (6AM Workshirts). Unlike absorbent fabrics that hold onto moisture, wicking fabrics rapidly move it, preventing a clammy sensation and reducing chafing.

Quick-Drying: Once sweat is wicked to the fabric’s surface, quick-drying technology takes over. Fabrics designed for rapid drying spread the moisture across a larger surface area, allowing it to evaporate quickly into the air. This rapid evaporation is critical for regulating body temperature, as it actively cools the wearer (TrueRevo). Without this rapid evaporation, even wicked moisture could lead to cooling a wearer too much in cold conditions, or simply remaining damp.

Breathability: Complementing wicking and quick-drying, breathability refers to a fabric’s ability to allow air to pass through it. This airflow facilitates the evaporation of sweat and prevents heat from becoming trapped against the skin, contributing significantly to overall comfort and thermal regulation. Together, these scientific principles ensure that the wearer remains dry, comfortable, and at an optimal body temperature, even during strenuous activities or in warm conditions.

Exploring Various Anti-Sweat Fabric Types for Apparel Production

The landscape of anti-sweat materials is diverse, encompassing both synthetic and natural fibers, often in specialized weaves or blends to optimize performance. Product developers must understand the unique characteristics of each to select the appropriate garment fabric.

Synthetic Fabrics: These are often the go-to for high-performance anti-sweat apparel due to their inherent hydrophobic (water-repelling) properties, which enable efficient moisture transfer.

- Polyester: A highly popular choice, polyester excels at moisture-wicking and quick-drying. It is durable, resistant to shrinking and stretching, and holds color well. Brands often use specially engineered polyester fibers (like Dry-fit) that enhance its wicking capabilities (TrueRevo).

- Nylon: Known for its strength, elasticity, and smooth feel, nylon also possesses excellent wicking properties. It is often favored for base layers and performance outerwear due to its durability and resistance to abrasion (Thread Logic).

- Rayon: While derived from natural cellulose, rayon is processed to enhance its moisture management. It offers a soft drape and can be quite absorbent, making it suitable for certain types of casual wear where breathability is key (Thread Logic).

- Spandex (Lycra): Though not primarily a wicking fiber, spandex is crucial for adding stretch and shape retention to blends, allowing garments to move with the body and maintain close contact for efficient wicking.

Natural Fibers: While generally more absorbent, certain natural fibers, particularly when treated or blended, can offer significant anti-sweat properties, often with superior hand feel and sustainability profiles.

- Cotton: High-quality, lightweight cotton is inherently breathable and offers good airflow. However, traditional cotton absorbs and holds onto moisture, which can lead to a damp, heavy feel. Special processing or blends are required for cotton to exhibit true anti-sweat properties (Thompson Tee).

- Merino Wool: Despite being wool, merino is remarkably fine and soft, with natural temperature-regulating and odor-resistant properties. It can wick moisture effectively and feel dry even when damp.

- Bamboo Viscose: Known for its softness and excellent moisture absorption and wicking capabilities, bamboo viscose is a comfortable and increasingly popular natural option.

- Linen & Silk: These fibers are highly breathable and comfortable in warm conditions. While they absorb moisture, their structure can allow for quicker drying than heavy cotton, though they are less performance-oriented than synthetics (CTNBEE).

Blends and Specialized Weaves: Often, the best performance comes from blending different fibers, such as polyester/spandex or cotton/Lycra blends, to combine the strengths of each material (Thread Logic). Additionally, specialized fabric constructions like double knits, pique, and mesh enhance breathability and wicking efficiency by creating channels for moisture movement and improved airflow.

Key Factors in Selecting The Ideal Anti-Sweat Fabric for Your Line

Choosing the optimal anti-sweat fabric for an apparel line requires a meticulous evaluation of several key factors that directly impact performance, comfort, and marketability. Product developers must weigh these considerations carefully to align fabric properties with the garment’s intended use.

Material Composition: The blend of fibers dictates much of the fabric’s performance. Synthetics (polyester, nylon) excel in wicking and drying, while natural fibers (merino wool, specialized cotton) can offer a more comfortable hand feel, breathability, and natural odor resistance. Blends (e.g., polyester-spandex) offer a balance of stretch, durability, and moisture management.

Weight and Thickness: Fabric weight significantly impacts breathability and application suitability. Lighter, thinner materials, often with finer yarns, enhance airflow and reduce sweat buildup, making them ideal for high-exertion activities or hot climates (REI Expert Advice). Conversely, heavier fabrics might be suitable for colder environments where some insulation is desired, while still needing to manage internal moisture.

Stretch and Recovery: The fabric’s ability to stretch and return to its original shape is vital for comfort, range of motion, and garment fit, particularly in activewear and form-fitting designs. This is typically achieved through the inclusion of elastane (spandex/Lycra).

Durability: Apparel must withstand repeated use and washing without losing its functional properties. Factors like abrasion resistance, tear strength, and pill resistance contribute to the longevity of the garment, offering long-term value to the end-user.

Hand Feel and Comfort: The tactile quality of the fabric is critical for consumer acceptance. While synthetic fabrics offer superior moisture management, some may retain odor over time, whereas natural options like cotton can feel softer but may not dry as quickly (Thompson Tee). Balancing performance with a pleasing feel is crucial for market success.

Sustainability: With increasing environmental consciousness, product developers are prioritizing eco-friendly options. This includes fabrics made from recycled materials (e.g., recycled polyester), bio-based fibers, or those produced with lower environmental impact.

Advanced Moisture Management Features: Beyond basic wicking, consider fabrics with specialized weaves or treatments that enhance quick-drying properties and overall breathability (REI Expert Advice). Some fabrics also integrate anti-microbial treatments to control odor.

Application Spotlight: Where Anti-Sweat Fabrics Excel in Apparel

The versatility of anti-sweat fabrics has led to their widespread adoption across various apparel categories, each with distinct performance requirements. Their ability to manage moisture and enhance comfort makes them indispensable for both specialized and everyday clothing.

Sportswear and Activewear: This is arguably the most prominent application. From running shirts and cycling jerseys to yoga pants and base layers, anti-sweat fabrics are essential. They help athletes stay dry, prevent chafing, and regulate body temperature, allowing sweat to evaporate faster and enhancing the body’s natural cooling system (Chiuvention). The absence of visible sweat marks is an added aesthetic benefit for consumers.

Workwear: For professions that involve physical exertion or environments with high temperatures, such as construction, healthcare, industrial settings, or even office wear in warm climates, anti-sweat workwear provides significant comfort. It reduces the risk of heat stress and maintains professionalism by preventing visible sweat stains.

Casual Apparel: Beyond performance-specific garments, anti-sweat properties are increasingly sought after in everyday casual wear. Lightweight, breathable fabrics, including specially treated cotton, offer enhanced comfort for daily activities, travel, and warm weather outfits (Thompson Tee). They address the common discomfort of sweating in casual settings.

Intimate Wear and Undergarments: Base layers, socks, and underwear benefit immensely from moisture-wicking and quick-drying properties. This application is crucial for hygiene, preventing skin irritation, and maintaining personal comfort throughout the day, regardless of activity level.

Emerging Applications: As fabric technology advances, anti-sweat properties are being integrated into diverse categories such as sleepwear for temperature regulation, specialized outdoor gear for extreme conditions, and even formal wear where discreet sweat management is desired. The core need for dryness and comfort drives innovation across the entire apparel spectrum.

The Business Advantage: Why Invest in High-Quality Anti-Sweat Fabrics for Your Brand

For apparel brands, the decision to invest in high-quality anti-sweat fabrics is not merely about product features; it’s a strategic business imperative that yields substantial competitive advantages and fosters long-term growth.

Enhanced Product Performance: At the forefront, superior fabrics translate directly to superior product performance. Garments made with advanced anti-sweat materials genuinely deliver on their promise of keeping wearers dry, cool, and comfortable, whether during an intense workout or a demanding workday. This ensures consumers experience the intended benefits, reinforcing the product’s value proposition. Investing in breathable fabrics directly contributes to enhanced performance and daily comfort (Q Clothier).

Increased Customer Satisfaction and Loyalty: In a market saturated with options, comfort and functionality are key differentiators. Products that effectively manage sweat and keep users comfortable lead to higher satisfaction rates. This positive experience builds customer loyalty, encouraging repeat purchases and positive word-of-mouth referrals. Preventing visible sweat marks also significantly enhances user confidence and comfort (Chiuvention).

Improved Brand Reputation: A consistent commitment to quality and performance elevates a brand’s reputation. Brands known for their effective anti-sweat apparel are perceived as innovative, reliable, and customer-focused. High breathability further prevents overheating, contributing to a premium perception (Jolger). This positive image can command higher price points and attract a more discerning customer base.

Competitive Differentiation: The apparel market is fiercely competitive. Offering garments with superior anti-sweat capabilities provides a distinct competitive edge. It allows brands to stand out from competitors who might use lower-grade materials, attracting consumers who prioritize comfort, performance, and advanced functionality in their clothing choices. This differentiation can be leveraged in marketing and sales strategies to capture a larger market share.

Sourcing Your Anti-Sweat Fabrics: A Wholesale Guide for B2B Buyers

For product developers and designers, successful apparel production hinges on sourcing the right materials. When it comes to wholesale anti-sweat fabric, a strategic approach to selecting a fabric supplier is crucial for quality, consistency, and cost-efficiency.

Identifying Reliable Suppliers: The foundation of effective sourcing is finding partners who are experienced and trustworthy. It is essential to research fabric vendors, assessing their track record, industry reputation, and commitment to quality. Visiting trade shows, requesting samples, and reviewing certifications are vital steps. Look for suppliers who can demonstrate their expertise in performance fabrics and offer minimum order quantities (MOQs) that align with your brand’s production needs (Fashion Brain Academy).

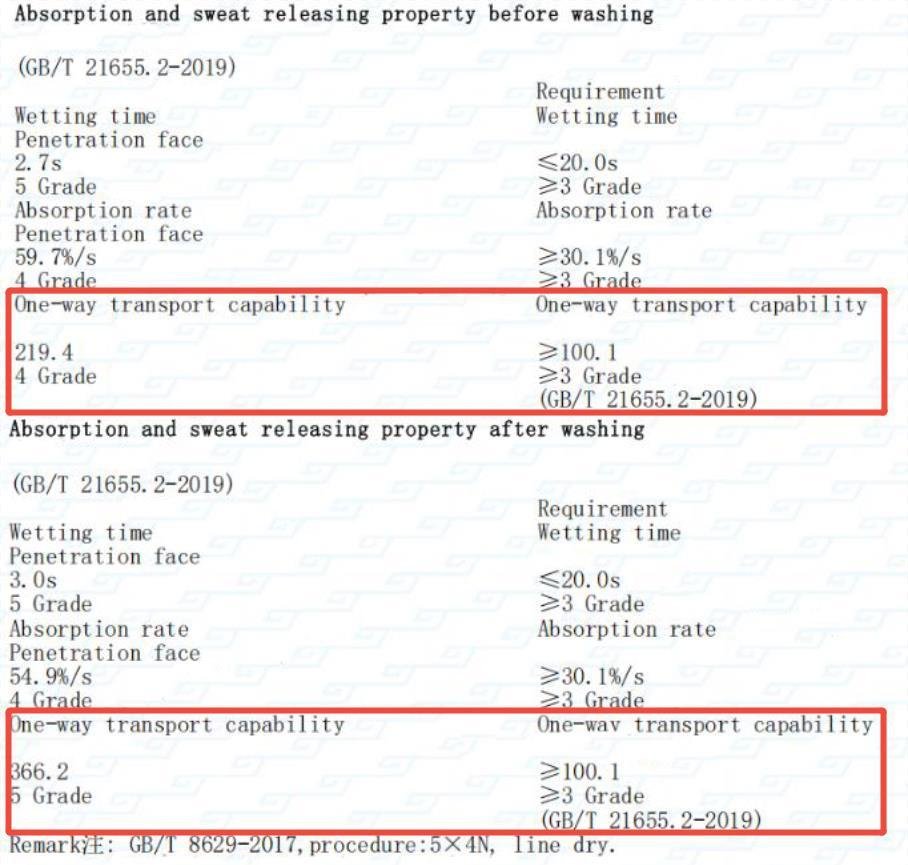

Understanding Quality Standards and Testing: Not all anti-sweat fabrics are created equal. Inquire about the supplier’s quality control processes and relevant testing standards for moisture management (e.g., AATCC 195 for wicking, AATCC 201 for drying rate). Ensure the fabrics meet the performance metrics required for your specific apparel application. A reputable supplier should be transparent about their fabric specifications and testing results.

Minimum Order Quantities (MOQs): MOQs vary significantly between suppliers and fabric types. Larger manufacturers often have higher MOQs, which might be challenging for smaller or emerging brands. Discuss your anticipated order volumes early on to find a supplier whose MOQs are feasible for your production scale. Some suppliers offer tiered pricing based on volume, which can lead to better unit costs for larger orders.

Exploring Custom Fabric Solutions: For brands seeking a unique selling proposition, exploring custom fabric development with a supplier can be highly beneficial. This allows for the creation of proprietary blends, weaves, or finishes tailored to specific performance needs, aesthetic desires, or sustainability goals. Custom solutions typically involve higher MOQs and longer lead times but can result in highly differentiated products.

Supply Chain Transparency and Ethics: As consumers demand greater accountability, sourcing fabrics from suppliers committed to ethical labor practices and environmental sustainability is becoming increasingly important. Inquire about their certifications (e.g., OEKO-TEX, GRS for recycled content) and supply chain transparency. This not only mitigates risks but also enhances your brand’s appeal to socially conscious consumers.

To illustrate the varying approaches to fabric sourcing, consider the following general comparison:

| Sourcing Option | Pros | Cons | Best For |

|---|---|---|---|

| Direct from Mill | Lowest cost per unit (large volume), custom development, full control over specifications. | Very high MOQs, long lead times, complex logistics, requires in-depth fabric knowledge. | Large, established brands with specific needs and high production volumes. |

| Wholesale Fabric Supplier/Distributor | Lower MOQs than mills, wider range of fabrics, faster delivery, easier communication. | Slightly higher unit cost, less customization than mills. | Small to medium-sized brands, those needing variety or quicker turnaround. |

| Fabric Agent/Broker | Access to global network, expertise in sourcing, handles negotiations. | Adds an intermediary cost, less direct control. | Brands new to sourcing, those seeking specialized or hard-to-find fabrics. |

Elevate Your Apparel: The Future of Comfort with Advanced Anti-Sweat Fabrics

The journey through the world of anti-sweat materials reveals their undeniable value in today’s dynamic apparel industry. For product developers and designers, the strategic integration of these advanced materials is no longer a niche consideration but a fundamental requirement for creating compelling and competitive apparel lines.

The continuous innovation in fabric technology promises an exciting future for comfort. Emerging trends point towards even more sophisticated solutions, including bio-based fibers that offer sustainable alternatives without compromising performance, and smart textiles capable of dynamically adapting to environmental conditions or wearer needs (Q Clothier). Future anti-sweat fabrics are being engineered to act like “tiny pumps,” actively drawing sweat away from the skin and efficiently dispersing it across the fabric’s surface for optimal evaporation (330 Trading Co.). This ongoing evolution will push the boundaries of comfort, durability, and sustainability.

By meticulously selecting and incorporating advanced anti-sweat fabrics, brands can not only meet but exceed consumer expectations, building a reputation for excellence and innovation. The investment in these materials ensures that garments offer unparalleled comfort, performance, and a competitive edge, truly elevating the apparel experience for the end-user.

Conclusion

The strategic integration of anti-sweat fabrics is a cornerstone for innovation and success in the modern apparel industry. Product developers and designers who deeply understand the scientific principles behind moisture management, the diverse array of fabric types, and the critical factors influencing material selection are uniquely positioned to craft superior apparel lines. This commitment to advanced fabric technology not only enhances product performance and customer satisfaction but also fortifies brand reputation and provides a crucial competitive advantage. As fabric innovations continue to evolve, staying at the forefront of these developments will be key to meeting the increasing consumer demand for comfort, functionality, and sustainability in clothing.

Sources

Looking For Textile Supplier? Get Wholesale Price From Us Now

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)