Abstract

Launching a clothing line requires meticulous planning, with fabric sourcing standing as a foundational pillar for success. This comprehensive guide is designed for emerging fashion entrepreneurs, offering a step-by-step methodology to identify, assess, and secure reliable fabric suppliers. It navigates the complexities from understanding precise fabric requirements, including specialized materials like anti-sweat fabric, to mastering supplier vetting, sample testing, negotiation strategies, and the cultivation of enduring professional relationships. By adhering to the principles outlined herein, brands can establish a robust supply chain, ensuring product quality and fostering sustainable growth in a competitive market.

Table of Contents

- Understanding Your Brand’s Fabric Needs: Beyond Basic Cloth Material

- Where to Find Reputable Fabric Suppliers: Online vs. Offline Sourcing

- Essential Criteria for Vetting Potential Fabric Suppliers and Partners

- The Importance of Samples: Testing Your Garment Fabric and Anti-Sweat Material

- Navigating Negotiations and Contracts with Your Chosen Fabric Supplier

- Building Long-Term Relationships with Top Fabric Suppliers for Sustained Growth

Understanding Your Brand’s Fabric Needs: Beyond Basic Cloth Material

The initial step in sourcing involves a profound understanding of your brand’s specific fabric requirements, extending far beyond merely identifying basic cloth material. This foundational analysis is crucial as fabric choice profoundly impacts product comfort, aesthetic appeal, Durability, and ultimately, brand identity and customer satisfaction (Tapstitch Blog). To effectively identify the ideal materials for your clothing line, consider the following aspects:

- Brand Vision and Aesthetic: Define the overarching theme and style of your brand. Is it luxury, casual, athletic, or eco-conscious? The aesthetic will dictate fabric textures, drapes, and finishes.

- Target Market and End-Use: Understand who your customer is and how they will use your garments. For activewear, performance characteristics like moisture-wicking and breathability are paramount. For everyday wear, comfort and durability might take precedence. This will lead to exploring options such as wholesale anti-sweat fabric for athletic lines or durable cottons for basics.

- Functional Requirements: Beyond aesthetic, consider functional needs. Do your garments require stretch, water resistance, UV protection, or thermal regulation? Specific applications might demand specialized textiles. For instance, creating a line for high-intensity workouts necessitates materials designed to manage sweat effectively.

- Sustainability Goals: If your brand is committed to ethical and environmental responsibility, your fabric choices must reflect this. Research sustainable alternatives such as organic cotton, recycled polyester, Tencel, or hemp. Understanding the production methods and certifications of these materials is vital.

- Garment Construction and Design: The intended garment construction also influences fabric selection. Some designs require stiff, structured fabrics, while others demand soft, flowing materials. Knowledge of how fabrics are manufactured can provide insights into their suitability for specific designs (Bryden Apparel).

Thoroughly defining these needs creates a clear brief for potential fabric suppliers, streamlining the sourcing process and ensuring alignment with your brand’s core values and product goals.

Caption: Understanding your brand’s specific fabric needs is the first step towards successful sourcing.

Where to Find Reputable Fabric Suppliers: Online vs. Offline Sourcing

Once your fabric needs are clearly defined, the next challenge is locating reputable fabric suppliers. The sourcing landscape offers a blend of online and offline channels, each presenting distinct advantages, especially when considering purchasing fabric in bulk (Fashinza).

- Online Sourcing Channels:

- B2B Marketplaces: Platforms like Alibaba, GlobalSources, and Texworld USA Digital offer extensive directories of suppliers globally. These platforms allow you to filter by fabric type, minimum order quantity (MOQ), and certifications.

- Specialized Fabric Wholesalers’ Websites: Many reputable fabric wholesalers operate their own e-commerce sites, allowing direct browsing and purchasing. Websites like Fabric Mart have been noted for their offerings, though careful verification of fabric descriptions is always recommended (Reddit r/sewing).

- Industry-Specific Databases: Some trade associations or textile directories maintain lists of certified or specialized suppliers.

Advantages of Online: Convenience, global reach, quick comparison of prices and specifications, access to a vast array of materials.

Disadvantages of Online: Inability to physically inspect fabric before sampling, potential for misrepresentation, higher risk of scams if not properly vetted. - Offline Sourcing Channels:

- Trade Shows and Exhibitions: Attending textile trade shows (e.g., Première Vision, Texworld, Apparel Sourcing) is invaluable. These events provide an opportunity to physically touch fabrics, meet fabric suppliers face-to-face, discuss requirements in detail, and build initial relationships.

- Local Fabric Districts/Wholesalers: Depending on your location, major cities often have fabric districts or wholesale markets where you can find a variety of suppliers. This allows for immediate inspection and often quicker access to samples.

- Referrals and Industry Networks: Leveraging your network within the fashion industry can lead to highly reliable supplier recommendations. Personal referrals often come with implicit trust and valuable insights into supplier performance.

- Sourcing Agents: For brands seeking highly specialized fabrics or those with limited time for extensive research, a fabric sourcing agent can be a valuable partner. They have established networks and expertise in identifying suitable suppliers.

Advantages of Offline: Direct interaction, immediate sensory evaluation of fabrics, stronger relationship building potential, greater transparency regarding production processes.

Disadvantages of Offline: Time-consuming, limited geographical reach compared to online, travel expenses.

A hybrid approach, combining the extensive reach of online resources with the personal touch and verification possible through offline channels, often yields the most effective results for finding high-quality wholesale fabric.

Essential Criteria for Vetting Potential Fabric Suppliers and Partners

Vetting potential fabric suppliers is a critical phase that ensures the reliability, quality, and ethical alignment of your supply chain. This process involves evaluating several key factors to determine if a supplier can meet your brand’s specific needs and standards (Source of Fabric). When choosing a supplier or a sourcing agent, consider the following:

| Criterion | Description and Importance |

|---|---|

| Quality Control Standards | Inquire about their quality assurance processes. Do they have certifications (e.g., ISO, Oeko-Tex)? How do they ensure consistency in fabric weight, color, and finish? Robust QC is non-negotiable for consistent garment fabric quality. |

| Certifications and Compliance | Verify relevant certifications, especially for specialized fabrics (e.g., GOTS for organic, GRS for recycled, Bluesign for sustainable textile production). This indicates adherence to industry standards and ethical practices. |

| Minimum Order Quantities (MOQs) | Understand their MOQs for different fabric types. These can vary significantly and impact your initial investment. Ensure their MOQs align with your production scale, especially if you are starting small. |

| Production Lead Times | Clarify the typical lead times from order placement to delivery. Longer lead times require more precise inventory planning. Delays can disrupt production schedules and market entry. |

| Ethical and Environmental Practices | Investigate their commitment to ethical labor practices and environmental sustainability. This includes fair wages, safe working conditions, waste management, and energy efficiency. This aligns with responsible sourcing and can be a key brand differentiator. |

| Communication and Responsiveness | Assess their communication clarity and responsiveness during initial inquiries. Good communication is vital for problem-solving, managing expectations, and maintaining a smooth supply chain. |

| Pricing Structure and Payment Terms | Understand their pricing models (per yard/meter, per roll) and standard payment terms (e.g., upfront deposit, payment upon delivery). Ensure transparency and competitiveness. |

| References and Reputation | Request references from other clients, if possible. Research their industry reputation through reviews, forums, or discussions with peers. This provides insight into their reliability and service quality. |

A thorough vetting process, much like choosing a sourcing agent, requires careful consideration of how well a supplier aligns with your specific business needs and values (LinkedIn Pulse). Prioritizing these criteria will help establish a foundation of trust and efficiency with your chosen partners.

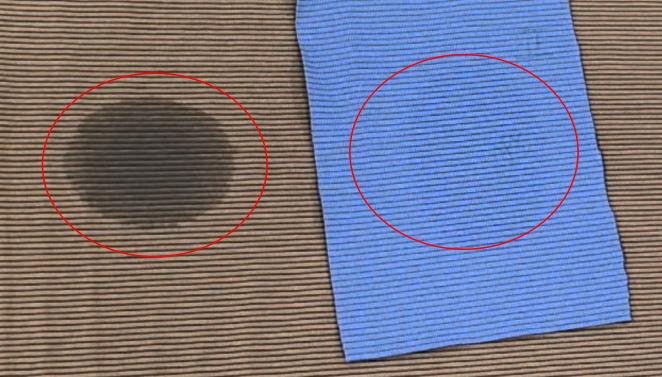

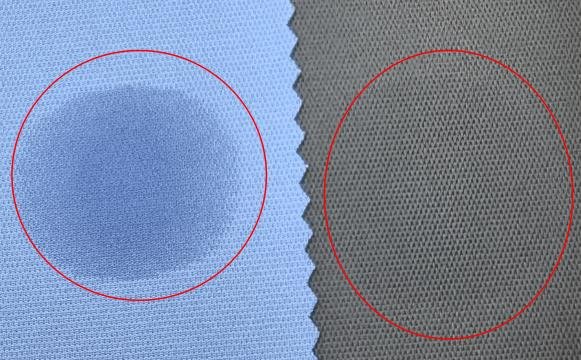

The Importance of Samples: Testing Your Garment Fabric and Anti-Sweat Material

Once potential fabric suppliers are identified, ordering and rigorously testing samples is an indispensable step before committing to bulk orders. Samples serve as the tangible proof of a supplier’s claims and allow for critical evaluation of the material’s suitability for your clothing line. This stage is crucial for verifying that the garment fabric meets all design, quality, and performance specifications.

Key aspects to test for include:

- Quality and Hand-feel: Physically inspect the fabric for weaving consistency, potential defects, and overall quality. Feel its texture and drape to ensure it aligns with your design vision and desired comfort level.

- Color Fastness: Test how well the color holds up to washing, rubbing, and exposure to light. Poor color fastness can lead to customer dissatisfaction.

- Shrinkage: Wash and dry a sample according to recommended care instructions to assess its shrinkage rate. This is vital for accurate pattern making and sizing.

- Durability and Performance: For specialized materials like wholesale anti-sweat fabric, perform specific tests related to its intended use. This could include moisture-wicking capabilities, breathability, stretch recovery, and abrasion resistance. Laboratory testing can provide objective data on performance attributes (Inspectorio).

- Print and Embellishment Compatibility: If your designs involve printing, embroidery, or other embellishments, test these processes on samples to ensure the fabric reacts as expected and the final result meets your aesthetic standards.

- Sewability: Work with your pattern makers or seamstresses to assess how easily the fabric can be cut and sewn. Some fabrics may require specialized needles or techniques.

Receiving and evaluating samples allows you to visualize and confirm design suitability before moving into full production, preventing costly errors down the line (Seam Apparel). This iterative process of sampling and feedback ensures that the chosen fabric is perfect for your specific garment.

Navigating Negotiations and Contracts with Your Chosen Fabric Supplier

After selecting a Fabric Supplier based on thorough vetting and sample approval, the focus shifts to securing favorable terms through effective negotiation and clear contractual agreements. Successful negotiation is not solely about price; it encompasses lead times, payment terms, quality assurance, and dispute resolution.

Key strategies for negotiation include:

- Know Your Needs and Budget: Before entering discussions, have a clear understanding of your required quantities, desired delivery timelines, and budget constraints (LinkedIn Advice). This preparedness enables you to articulate your position clearly and identify areas for compromise.

- Be Transparent and Respectful: Open and honest communication fosters trust. Be upfront about your expectations and be respectful of the supplier’s constraints. A collaborative approach is often more effective than an aggressive one.

- Leverage Volume (if applicable): If you plan to order larger quantities of wholesale cloth material, use this as leverage for better per-unit pricing. Discuss potential future orders and long-term partnership opportunities to incentivize better initial terms.

- Understand Payment Terms: Negotiate payment schedules that align with your cash flow, such as a percentage upfront and the remainder upon delivery or after quality inspection. Clearly define currencies and methods of payment.

- Consider Non-Price Concessions: If price negotiation reaches an impasse, explore other concessions such as reduced MOQs for initial orders, expedited shipping options, or extended credit terms.

- Seek Multiple Quotes: Engaging with several potential fabric suppliers allows you to compare offers and strengthen your negotiating position. Knowing market rates gives you an advantage (Fabriclore).

Once terms are agreed upon, a comprehensive contract is essential. This document should explicitly detail:

- Fabric specifications (type, composition, weight, color, finish)

- Quantity and unit pricing

- Total cost

- Payment schedule and terms

- Delivery dates and logistics (Incoterms)

- Quality control standards and acceptance criteria

- Procedures for handling defective goods or late deliveries

- Confidentiality clauses, if necessary

- Dispute resolution mechanisms

A well-drafted contract serves as a protective framework for both parties, ensuring a reliable and consistent supply chain and minimizing potential misunderstandings.

Caption: Clear communication and a comprehensive contract are vital for successful supplier partnerships.

Building Long-Term Relationships with Top Fabric Suppliers for Sustained Growth

The relationship with your Fabric Supplier extends beyond a transactional exchange; it is a partnership that can significantly influence your brand’s longevity and capacity for innovation. Fostering strong, lasting relationships is key to ensuring ongoing quality, preferential treatment, and support for your growing brand (Makemine).

Strategies for cultivating robust supplier relationships include:

- Consistent and Transparent Communication: Regular, clear, and honest communication builds trust. Keep suppliers informed of your future plans, potential increases in order volumes, or any challenges you might face. Be proactive in addressing issues and providing feedback.

- Fairness and Timeliness in Payments: Adhering to agreed-upon payment terms is fundamental. Consistent and timely payments demonstrate reliability and professional courtesy, making your brand a preferred client.

- Mutual Respect and Understanding: Recognize that suppliers are businesses with their own challenges and limitations. Treat them as partners, not just vendors. Understand their production cycles, holidays, and potential constraints.

- Providing Constructive Feedback: When issues arise, offer feedback that is specific, constructive, and aimed at improvement rather than blame. This collaborative problem-solving approach strengthens the partnership.

- Exploring Joint Innovation: Collaborate with your suppliers on new fabric developments, sustainable practices, or process improvements. This can lead to unique material solutions and give your brand a competitive edge. This is particularly relevant for brands aiming to build strong relationships with sustainable textile suppliers (LinkedIn Advice).

- Visiting Supplier Facilities: If feasible, periodic visits to your supplier’s facilities can deepen understanding of their operations, build personal rapport, and demonstrate your commitment to the partnership.

- Acknowledging Good Performance: Publicly or privately acknowledge when a supplier performs exceptionally well. Positive reinforcement encourages continued high standards.

By investing time and effort into these relationships, you secure a reliable source of high-quality materials and gain a valuable ally in navigating the complexities of the fashion industry. A strong supplier network becomes an invaluable asset, contributing to your brand’s resilience and capacity for sustained growth.

Summary

Embarking on the journey of finding the right fabric supplier is a strategic imperative for any new clothing brand. It demands a holistic approach that begins with a precise definition of your brand’s unique fabric needs, encompassing not just aesthetic appeal but also functional specifications and ethical considerations. The subsequent methodical exploration of online and offline sourcing channels, coupled with rigorous vetting based on quality, reliability, and ethical practices, forms the backbone of a resilient supply chain. The importance of sampling cannot be overstated, as it provides the tangible assurance required before committing to production. Finally, adept negotiation and the cultivation of strong, long-term partnerships are not merely transactional necessities but foundational elements for fostering innovation, ensuring consistent quality, and paving the way for sustained growth in a dynamic industry. The diligence applied in these early stages directly translates into the quality and reputation of your final product, making a robust supplier relationship an indispensable cornerstone of brand success.

Sources

Looking For Textile Supplier? Get Wholesale Price From Us Now

![[JuncoMaterials]Sourcing from China: 5 Surprising Benefits of Using Chinese Fabric Suppliers](https://materials.juncosports.com/wp-content/uploads/2025/07/image-23.jpg)

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)