Abstract

The global apparel industry is characterized by dynamic consumer demands and intricate supply chains, placing immense pressure on brands to optimize operations while maintaining quality and cost-effectiveness. Many brands currently grapple with inefficiencies, escalating costs, and inconsistent product quality, largely stemming from suboptimal relationships with their material providers. This article delves into the strategic imperative of collaborating with a top-tier Clothing Material Supplier, exploring how such a partnership transcends mere transactional exchanges to fundamentally enhance a brand’s operational efficiency, product integrity, and ultimately, its financial bottom line. By offering a strategic perspective, we aim to provide insights for brands seeking to mitigate current supply chain challenges and foster sustainable growth through superior material sourcing.

Table of Contents

- Navigating Supply Chain Headaches: Why Your Current Supplier Might Be Holding You Back

- The Direct Impact of a Top Clothing Material Supplier on Your Cost Savings

- Elevating Product Quality: How Premium Fabrics Boost Your Brand’s Reputation

- Ensuring Supply Chain Stability and Speed-to-Market with a Reliable Partner

- Beyond Basics: Accessing Innovative and Specialized Fabric Solutions for Competitive Advantage

- Building a Strategic Alliance: More Than Just a Transactional Relationship

- Key Criteria: How to Identify Your Next Top Clothing Material Supplier

- Partnering for Profit: Fueling Your Brand’s Bottom Line with the Right Fabric Partner

Navigating Supply Chain Headaches: Why Your Current Supplier Might Be Holding You Back

Many fashion and apparel brands frequently encounter significant obstacles within their existing supply chains, impacting everything from production timelines to profitability. Common frustrations include unpredictably high costs, inconsistent material quality, and general unreliability. These issues often stem from a lack of robust supplier performance tracking and inadequate root-cause analysis, which can prevent original equipment manufacturers (OEMs) from making informed purchasing decisions and improving overall efficiency (Wipro). When a Fabric Supplier is not performing optimally, it can lead to increased total cost of ownership, making a seemingly low-cost option more detrimental than beneficial in the long run (LinkedIn). Recognizing these pain points is the first step toward understanding the profound benefits a superior material partner can offer.

The Direct Impact of a Top Clothing Material Supplier on Your Cost Savings

A strategic partnership with a leading Clothing Material Supplier directly translates into tangible cost reductions across various operational facets. One primary avenue for savings is through economies of scale; purchasing large quantities of materials directly from a wholesale supplier often secures significant discounts compared to retail pricing (Source of Fabric). Beyond initial purchase prices, a superior supplier contributes to cost optimization by ensuring higher quality materials, which reduces waste from defects and rework. They often possess advanced production techniques that minimize material waste and optimize labor costs. By focusing on critical areas such as material costs and adopting efficient production methods, brands can achieve substantial cost savings, thereby improving overall profitability (ApparelMagic). These efficiencies extend beyond raw material acquisition to encompass a streamlined, more economical production process.

Elevating Product Quality: How Premium Fabrics Boost Your Brand’s Reputation

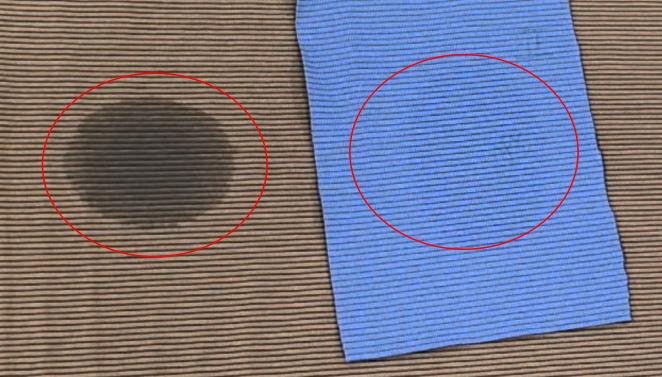

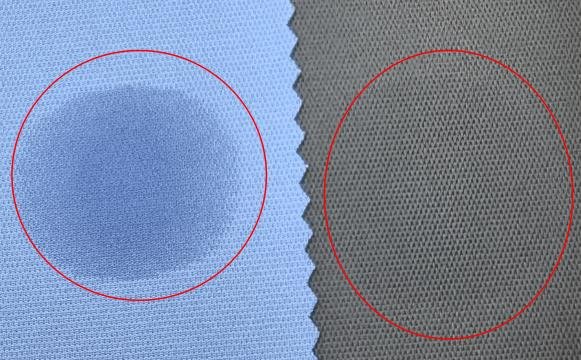

The quality of the materials used in production is intrinsically linked to the final product’s excellence and, by extension, a brand’s reputation. Sourcing high-quality, consistent garment fabric directly improves the appeal, durability, and material performance of apparel. This is particularly crucial for specialized products, such as those requiring wholesale anti-sweat fabric, where material performance is a key differentiator. Premium fabrics contribute to greater product longevity, generating more positive impressions among consumers and enhancing the brand’s perception in the market (Bamko). Furthermore, consistent material quality significantly reduces product returns due to defects or customer dissatisfaction, safeguarding the brand’s reputation and optimizing financial returns. Investing in quality fabrics is not merely a cost but a strategic investment in brand equity and customer loyalty.

Ensuring Supply Chain Stability and Speed-to-Market with a Reliable Partner

In today’s fast-paced market, supply chain stability is paramount for uninterrupted production and rapid product launches. A truly dependable clothing material supplier plays a critical role in achieving this by ensuring on-time delivery and consistent material availability. Organizations rely heavily on the global supply chain community, and disruptions at any point—such as a supplier experiencing low inventory—can create a detrimental ripple effect that slows down the entire chain (Paramount Global). A reliable partner mitigates these risks through robust inventory management practices and a commitment to delivery schedules, directly contributing to operational efficiency. This stability, in turn, supports faster product development and launch cycles, enabling brands to bring new designs to market swiftly and capitalize on emerging trends. Building trust through effective vetting techniques is essential for securing such reliable partnerships (Supply Chain Gamechanger).

Beyond Basics: Accessing Innovative and Specialized Fabric Solutions for Competitive Advantage

The fashion industry thrives on innovation, and access to cutting-edge materials is a powerful differentiator. A top Fabric Supplier does more than just provide standard textiles; they offer a gateway to a diverse range of advanced and specialized fabric solutions. This can include high-performance wholesale anti-sweat fabric for athletic wear, sustainable cloth material options, or unique blends that offer novel textures and functionalities. Such innovation empowers brands to leverage new material properties for competitive advantage, moving beyond basic product offerings to meet evolving market demands and consumer preferences (Nearsure). By collaborating with a forward-thinking supplier, brands can introduce distinctive products that stand out, such as those featuring innovative fibers like NEOLAST, as seen in industry collaborations (Under Armour). This strategic advantage is crucial for maintaining relevance and capturing new market segments.

Building a Strategic Alliance: More Than Just a Transactional Relationship

The relationship with a material supplier should evolve beyond simple transactions to become a strategic alliance. This transformation involves moving from merely placing orders to cultivating a partnership rooted in trust, aligned goals, and mutual value (Union County CoC). A true strategic alliance develops organically over time, proving mutually beneficial for both organizations involved (Dr. Ivan Misner). It is characterized by open communication, shared objectives for continuous improvement, and collaborative innovation in fabric development or supply chain optimization. Such alliances foster an environment where both parties work together to solve challenges, identify opportunities, and build each other’s businesses through combined efforts, ultimately leading to greater resilience and sustained success for the brand.

Key Criteria: How to Identify Your Next Top Clothing Material Supplier

Selecting the ideal Clothing Material Supplier is a critical strategic decision that demands careful consideration of several key factors. Brands must identify a partner that aligns with their strategic objectives and directly addresses their specific pain points. The evaluation process should go beyond basic cost comparisons to include aspects like consistent quality control, proven reliability in delivery and communication, and the supplier’s capacity for new materials. Ethical practices and sustainability certifications are also increasingly important. To aid in this selection, brands should consider the following criteria (Ryzeal Sourcing):

| Criterion | Description | Why It Matters |

|---|---|---|

| Quality & Consistency | Adherence to specifications, minimal defects, consistent material properties. | Ensures product integrity and reduces returns. |

| Cost-Effectiveness | Competitive pricing, but also consideration of total cost of ownership (TCO). | Directly impacts profitability and long-term financial health. |

| Reliability & Delivery | On-time deliveries, accurate order fulfillment, responsiveness to issues. | Maintains production schedules and speed-to-market. |

| Innovation & Adaptability | Access to new materials, willingness to develop custom solutions, flexibility. | Keeps your brand competitive and responsive to market trends. |

| Communication & Transparency | Clear, open, and proactive communication regarding production, delays, etc. | Fosters trust and efficient problem-solving. |

| Ethical & Sustainable Practices | Compliance with labor laws, environmental standards, certifications. | Protects brand reputation and aligns with consumer values. |

Before making a final choice, it is essential to conduct thorough due diligence, compare different manufacturers based on specific business needs, and invest in building strong vendor relationships (Fashinza).

Partnering for Profit: Fueling Your Brand’s Bottom Line with the Right Fabric Partner

The decision to partner with an exceptional Fabric Supplier has far-reaching implications, fundamentally fueling a brand’s financial health, market position, and sustainable growth. This partnership encapsulates a multitude of benefits, ranging from substantial cost reductions through optimized sourcing and reduced waste to significant enhancements in product quality that strengthen brand reputation and customer loyalty (Classic Fashion). Moreover, a reliable fabric partner ensures supply chain stability and speed-to-market, allowing brands to respond agilely to market shifts. Access to innovative and specialized materials provides a crucial competitive edge, enabling differentiation and market leadership. Ultimately, prioritizing the right fabric partner is a strategic investment that pays dividends, not just in immediate profits, but in building a resilient, reputable, and sustainably growing brand. Notably, focusing on sustainable materials, for instance, has been shown to boost the bottom line for fashion brands (Vogue Business), highlighting the interconnectedness of strategic sourcing and financial success.

Conclusion

The choice of a Clothing Material Supplier extends beyond a simple purchasing decision; it is a fundamental strategic alignment that dictates a brand’s trajectory in a highly competitive and evolving market. Brands that proactively seek out and cultivate relationships with top-tier suppliers unlock a cascade of benefits—from optimized costs and superior product quality to enhanced supply chain resilience and access to critical innovation. In essence, the right material partner is not merely a vendor but a vital strategic asset, indispensable for safeguarding and bolstering a brand’s financial viability and long-term market leadership.

Sources

- Wipro: https://www.wipro.com/blogs/wipro-insights/whats-holding-you-back-from-a-connected-supply-chain/

- LinkedIn: https://www.linkedin.com/top-content/supply-chain-management/procurement-management-tips/

- Source of Fabric: https://www.sourceoffabric.com/why-you-should-consider-using-a-fabric-wholesale-supplier/

- ApparelMagic: https://apparelmagic.com/top-strategies-for-garment-cost-optimization-save-and-succeed/

- Search for Fabric: https://searchforfabric.com/blogs/search-for-fabric-blog/why-quality-fabric-is-important-for-your-store?srsltid=AfmBOoq75g1sTEmjWQnasOwayKO82TSq5tSeknZSPwiMiTrX13glAzKM

- Bamko: https://bamko.net/blog/premium-apparel-for-your-brand

- Paramount Global: https://www.paramountglobal.com/knowledge/strategies-for-supply-chain-stability/

- Supply Chain Gamechanger: https://supplychaingamechanger.com/building-trust-in-your-supply-chain-effective-vetting-techniques-for-reliable-partners/

- Nearsure: https://www.nearsure.com/services/enterprise-platforms-optimization/microsoft-solutions/microsoft-fabric-partners

- Under Armour: https://about.underarmour.com/en/stories/2024/01/celanese-and-under-armour-develop-innovative-new-neolast–fiber-.html

- Union County CoC: https://unioncountycoc.com/the-new-networking-why-strategic-alliances-are-better-for-your-business/

- Dr. Ivan Misner: https://ivanmisner.com/creating-strategic-alliances/

- Ryzeal Sourcing: https://ryzealsourcing.com/key-factors-selecting-clothing-supplier/

- Fashinza: https://fashinza.com/fabric/comparison/comparison-chart-to-identify-best-clothes-and-fabric-manufacturers/

- Classic Fashion: https://www.classicfashion.com/blog/choosing-the-right-apparel-manufacturing-partner-why-it-matters/

- Vogue Business: https://www.voguebusiness.com/sustainability/want-to-boost-profits-invest-in-sustainable-materials-textile-exchange

Looking For Textile Supplier? Get Wholesale Price From Us Now

![[JuncoMaterials]The Ultimate Guide to Finding a Fabric Supplier for Your New Clothing Brand](https://materials.juncosports.com/wp-content/uploads/2025/07/image-12.jpg)

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)