Introduction

When selecting fabrics for clothing, upholstery, or industrial use, buyers often see the term GSM listed in product descriptions. At first glance, this abbreviation can be confusing. What does it really mean? Why is it important? And how can it influence the performance of a garment or textile product?

For many in the textile industry, GSM is a daily measurement tool, but for new buyers or businesses exploring fabric sourcing, it may feel overly technical. However, the concept is actually quite simple once explained clearly. GSM provides a way to measure the weight of fabric, which directly affects how it feels, performs, and lasts over time. By learning how to understand GSM, you can make smarter choices, communicate better with suppliers, and select fabrics that fit your needs perfectly.

What Does GSM Mean?

GSM stands for grams per square meter. It is a measurement that tells you the weight of a fabric sample, based on the size of one square meter.

For example:

A heavier material, such as denim, may measure 350 GSM, making it much denser and stronger.

A fabric with 150 GSM means one square meter of the fabric weighs 150 grams.

This number is helpful because fabrics can look similar at first glance, but GSM provides a clear, objective way to compare them. Instead of only relying on touch or appearance, buyers can use GSM as a universal standard for fabric weight.

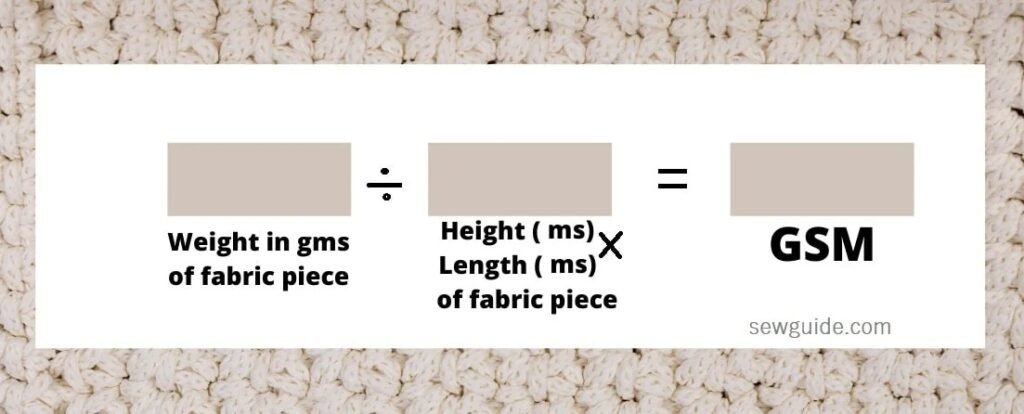

How Is GSM Calculated?

Manufacturers calculate GSM using a simple formula:

GSM = (Weight of fabric sample in grams ÷ Area of sample in square meters).

To simplify the process, a tool called a GSM cutter is often used. The cutter slices out a perfectly round fabric sample of a known size, usually 100 cm². This sample is then weighed on a precision scale, and the GSM is calculated based on the weight-to-area ratio.

For buyers without a GSM cutter, GSM can still be measured by cutting a fabric piece of known size and weighing it, although the results may not be as accurate. Fortunately, many suppliers include GSM in their product details, so buyers only need to confirm that the number matches their requirements.

Why Is GSM Important in Fabric?

Understanding GSM is crucial for both manufacturers and buyers because it provides clear information about fabric performance.

- Comfort and Wearability: Lightweight fabrics with lower GSM are airy and breathable, making them ideal for summer clothing. Higher GSM fabrics are warmer and heavier, perfect for winter garments.

- Durability: Higher GSM usually indicates stronger, denser fabrics that resist wear and tear. This makes them suitable for workwear, upholstery, or products that need long-lasting use.

- Cost Consideration: Fabrics with higher GSM generally require more raw material, which can increase the cost. Buyers must balance price with the functionality they require.

By using GSM as a guide, businesses can quickly match fabrics with product needs, saving time and reducing mistakes during sourcing.

GSM Ranges for Common Fabrics

Different fabrics fall into specific GSM ranges depending on their intended use. Here is a reference table:

| Fabric Type | Typical GSM Range | Common Uses |

|---|---|---|

| Lightweight Cotton | 100–160 GSM | T-shirts, summer wear |

| Medium Cotton | 160–220 GSM | Polo shirts, everyday apparel |

| Heavy Cotton | 220–300 GSM | Hoodies, sweatshirts |

| Polyester Blend | 120–250 GSM | Sportswear, yoga wear |

| Denim | 300–450 GSM | Jeans, jackets |

| Upholstery Fabric | 250–600 GSM | Sofas, curtains, cushions |

This table shows how GSM provides a quick way to identify if a fabric is suitable for lightweight summer wear, heavier winter garments, or industrial applications.

GSM vs. Fabric Quality: Clearing Misunderstandings

One of the most common misunderstandings is that higher GSM always means better quality. This is not true. GSM only measures fabric weight, not softness, breathability, or fiber quality.

For instance, a 200 GSM cotton T-shirt may feel much more comfortable than a 250 GSM polyester shirt, even though the polyester is heavier. Similarly, a lightweight silk with a low GSM can be luxurious and high-quality, while a heavier synthetic fabric may feel rough or uncomfortable.

Therefore, GSM should always be evaluated alongside other fabric characteristics:

- Fiber type (cotton, polyester, nylon, wool, etc.)

- Weave or knit structure (jersey, twill, canvas, etc.)

- Finishing treatments (brushed, coated, moisture-wicking, etc.)

Understanding this balance helps buyers avoid oversimplifying fabric decisions.

Choosing the Right GSM for Different Products

Different products require different GSM levels. Here are some general guidelines:

- T-shirts: Typically 120–180 GSM for lightweight comfort, or 180–200 GSM for premium structured tees.

- Polo Shirts: Usually 180–220 GSM, offering more thickness and durability.

- Yoga Wear & Sportswear: Often 180–250 GSM blends with spandex for flexibility and stretch.

- Hoodies & Sweatshirts: Range from 250–320 GSM, balancing warmth and breathability.

- Denim & Jackets: Often 300–450 GSM for durability and long-term wear.

- Home Textiles: Bedsheets may be 120–200 GSM for lightness, while curtains and upholstery fabrics often reach 300–600 GSM for strength.

By aligning GSM with product type, manufacturers and buyers can ensure the fabric performs as expected.

GSM and Seasonal Needs

Seasonality plays a big role in fabric selection. For hot and humid climates, low GSM fabrics allow better airflow, helping the wearer stay cool. In contrast, regions with colder winters often require higher GSM fabrics that provide warmth and insulation.

Global brands often adjust GSM across collections. A summer collection may use 140 GSM cotton for T-shirts, while the winter line uses 200 GSM for a thicker, warmer feel. In tropical countries, buyers often prioritize lightweight fabrics year-round, while customers in northern regions may demand heavier options. Understanding GSM helps suppliers adapt to diverse market needs.

Using GSM in Negotiations with Suppliers

For B2B buyers, GSM can be a valuable tool during sourcing and negotiations. When suppliers provide GSM details, buyers can:

- Compare options clearly without being misled by fabric appearance.

- Specify requirements upfront, ensuring samples match expectations.

- Avoid miscommunication since GSM is a universal measurement recognized worldwide.

For example, instead of asking for a “thicker T-shirt fabric,” a buyer can request “180 GSM cotton jersey.” This eliminates guesswork and helps establish professional trust between supplier and customer.

Conclusion

GSM may seem like a technical textile term, but it is actually a simple and practical measurement that every buyer can understand. It does not define quality by itself, but it provides essential information about fabric weight, durability, and suitability for different uses.

By learning to read GSM numbers, businesses can select fabrics with greater accuracy, reduce sourcing risks, and improve communication with suppliers. Whether you are choosing lightweight T-shirts, durable workwear, or strong upholstery fabric, GSM offers a reliable way to guide your decisions.

For B2B buyers, mastering GSM knowledge is more than just a technical detail—it is a competitive advantage in sourcing fabrics that meet customer demands and market trends.

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)