Abstract

Developing high-performance athletic and activewear necessitates the use of specialized textiles designed to manage the physiological responses of the human body during physical exertion. Among these, anti-sweat fabric stands out as a critical component, engineered to move moisture away from the skin, regulate temperature, and minimize discomfort. However, sourcing such advanced materials poses a unique challenge. This article explores why conventional fabric suppliers often lack the necessary expertise and capabilities to deliver technical textiles like anti-sweat material. It delineates the specific properties that define high-quality anti-sweat fabric, outlines key criteria for identifying specialized fabric suppliers, and elucidates the strategic advantages of partnering with experts in this niche. Ultimately, understanding these distinctions is paramount for brands aiming to produce genuinely effective and marketable activewear.Table of Contents

- The Unique Demands of Anti-Sweat Fabric: Beyond Standard Textile Production

- Why Your Current Fabric Supplier Isn’t Equipped for Performance Textiles

- Understanding Anti-Sweat Fabric: Key Properties for Athletic and Activewear

- What to Look for in Specialized Fabric Suppliers for Technical Materials

- The Strategic Advantage: Why Partnering with Expert Anti-Sweat Fabric Suppliers Matters

- Your Partner in Performance: Sourcing Quality Wholesale Anti-Sweat Fabric

- Elevate Your Activewear: Making the Right Choice of Garment Fabric Supplier

The Unique Demands of Anti-Sweat Fabric: Beyond Standard Textile Production

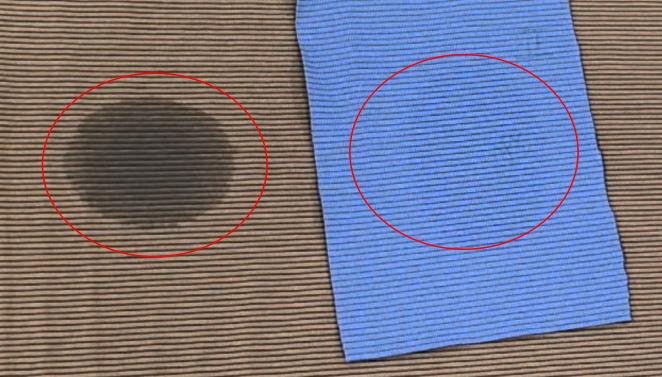

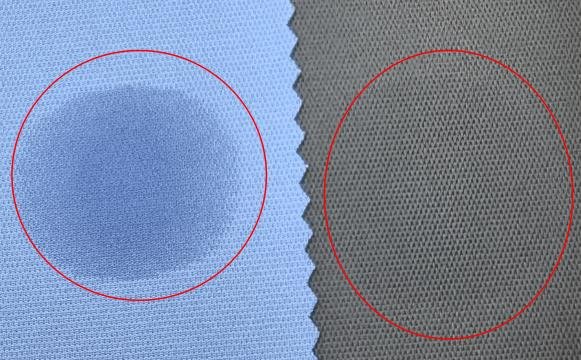

The creation of athletic and activewear that genuinely enhances performance and comfort requires a profound understanding of textile science, particularly when it comes to managing perspiration. Anti-sweat fabrics are not merely ordinary textiles; they are engineered solutions designed to interact dynamically with the body’s thermoregulatory processes. Unlike traditional materials such as cotton, which primarily absorb sweat, specialized anti-sweat fabrics are meticulously crafted to facilitate the rapid migration and evaporation of moisture from the skin’s surface. This complex process involves a delicate balance of fiber selection, yarn construction, and fabric finishing techniques (6AM Workshirts). The effectiveness of these materials stems from their ability to manage the spatial and temporal migration of sweat. While conventional fabrics might become saturated and heavy, leading to discomfort and potential chafing, anti-sweat textiles are designed to wick moisture away efficiently, maintaining a dry microclimate around the body (PMC). This fundamental difference necessitates manufacturing processes that go far beyond standard textile production, requiring specialized machinery, advanced chemical treatments, and precise structural engineering to achieve optimal performance characteristics. Therefore, the demands placed on the production of anti-sweat fabric are inherently more rigorous and technologically advanced than those for general-purpose cloth material.Why Your Current Fabric Supplier Isn’t Equipped for Performance Textiles

Many general-purpose fabric suppliers, while adept at producing a wide range of conventional textiles for various industries, often lack the specialized infrastructure, research and development capabilities, and technical expertise required for performance fabrics. Their manufacturing processes are typically optimized for cost-effective mass production of commodity fabrics, which do not demand the intricate engineering present in advanced textiles. Performance fabrics, including anti-sweat materials, represent a distinct category that has been transforming various sectors, from upholstery to apparel, due to their enhanced functional properties (Furniture Today).

- Lack of Specialized Machinery: Producing technical fabrics often requires state-of-the-art knitting and weaving technologies that allow for specific fiber arrangements, multi-layer constructions, or the incorporation of smart textile components. General suppliers may not have invested in such advanced equipment (Apex Mills).

- Absence of Dedicated R&D: Performance textiles are born from extensive research and development. This includes material science, fiber engineering, and chemical finishing. Most general suppliers do not have dedicated teams or facilities for this kind of innovative work.

- Limited Technical Expertise: Understanding how different fibers interact with moisture, how fabric structures influence breathability, or how finishes affect durability and antimicrobial properties requires specialized knowledge that is beyond the scope of traditional textile manufacturing.

- Inadequate Quality Control for Performance Attributes: While general suppliers conduct quality checks for aesthetics and basic durability, they typically lack the sophisticated testing protocols necessary to verify moisture-wicking efficiency, breathability ratings, or long-term antimicrobial effectiveness.

Understanding Anti-Sweat Fabric: Key Properties for Athletic and Activewear

For athletic and activewear brands, a clear understanding of the core properties that define effective anti-sweat fabric is essential. These properties are not merely buzzwords but represent specific technical attributes that directly impact wearer comfort, performance, and hygiene. High-quality performance fabrics are engineered with a combination of characteristics that work synergistically (Sport Casuals). The key properties to consider for anti-sweat fabric include:| Property | Description | Benefit for Activewear |

|---|---|---|

| Moisture-Wicking | The ability of a fabric to draw sweat away from the skin and transport it to the fabric’s outer surface, where it can evaporate rapidly. This is achieved through capillary action of specialized fibers. | Keeps the skin dry, prevents clamminess, reduces chafing, and maintains comfort during intense physical activity. |

| Breathability | The capacity of the fabric to allow air to circulate through its structure, facilitating heat and moisture vapor exchange between the body and the environment. | Prevents heat buildup, helps regulate body temperature, and enhances overall comfort, especially in warmer conditions. |

| Quick-Drying | The speed at which a fabric releases absorbed moisture and returns to a dry state. This is crucial for comfort during and after exercise, and for ease of care. | Minimizes the feeling of wetness, reduces the risk of chilling post-exercise, and makes garments ready for reuse faster. |

| Antimicrobial/Odor Control | The integration of technologies (e.g., silver ions, zinc pyrithione, or specific fiber structures) that inhibit the growth of odor-causing bacteria on the fabric surface. | Maintains freshness, prevents unpleasant body odor, and enhances hygiene, particularly important for activewear used in repetitive or extended sessions (TCA). |

| Durability | The fabric’s resistance to wear, tear, pilling, stretching, and color fading even after repeated washing and rigorous use. | Ensures the longevity of the garment, providing a better return on investment for consumers and reducing the need for frequent replacement. |

| Lightweight | The characteristic of the fabric being notably light, reducing bulk and allowing for unrestricted movement. | Contributes to the wearer’s agility and comfort, preventing the garment from feeling heavy or restrictive during activity. |

What to Look for in Specialized Fabric Suppliers for Technical Materials

Identifying a truly specialized fabric supplier for technical materials like anti-sweat fabric requires a diligent assessment beyond basic price and quantity. Brands must scrutinize a supplier’s capabilities, certifications, and track record to ensure they can consistently deliver the required performance and quality. Key criteria to evaluate include:- Specialization in Performance Textiles: Look for suppliers whose core business is technical or performance fabrics, not just a sideline. Their product portfolios should reflect a deep understanding of functional textile requirements (Jason Mills). Some renowned mills, like Schoeller in Switzerland, are recognized for their excellence in producing technical fabrics (Reddit – MYOG).

- Research and Development (R&D) Capabilities: A specialized supplier should demonstrate ongoing investment in R&D. This indicates their commitment to innovation, allowing them to offer the latest advancements in fiber technology, weaving techniques, and finishing treatments.

- In-house Testing and Quality Assurance: Demand evidence of rigorous testing protocols. This includes tests for moisture-wicking rates, breathability, stretch and recovery, durability, and antimicrobial effectiveness. Suppliers should have dedicated labs and transparent reporting.

- Certifications and Compliance: Verify relevant certifications such as Oeko-Tex Standard 100 (ensuring no harmful substances), bluesign (for sustainable textile production), or REACH compliance (EU chemical regulations). These certifications demonstrate adherence to high environmental and safety standards.

- Customization and Prototyping Capabilities: The ability to develop custom fabric constructions, colors, or finishes is invaluable for unique brand identities. A good supplier can work with you on prototypes and small-batch runs for testing.

- Scalability and Supply Chain Reliability: Ensure the supplier can meet your production volume needs as your brand grows. Assess their supply chain for resilience, ethical practices, and ability to deliver consistently and on time.

- Technical Support and Collaboration: A true partner offers expert guidance on fabric selection, technical specifications, and even garment design considerations related to fabric performance.

The Strategic Advantage: Why Partnering with Expert Anti-Sweat Fabric Suppliers Matters

The decision to partner with specialized fabric suppliers for anti-sweat materials extends beyond mere procurement; it constitutes a significant strategic advantage for any activewear brand. This collaboration profoundly impacts product quality, market competitiveness, and long-term brand reputation. The strategic benefits include:- Guaranteed Quality and Performance Consistency: Expert suppliers maintain stringent quality control measures tailored to technical fabrics. This ensures that every roll of fabric meets specified performance criteria, leading to consistent product quality and reliable consumer satisfaction. Essential fabric testing practices are crucial for athleisure brands to ensure their materials perform as expected (330 Trading).

- Accelerated Innovation and Market Responsiveness: Specialized suppliers are at the forefront of textile innovation. They possess the R&D capabilities to develop new fiber blends, fabric structures, and finishes, allowing brands to quickly integrate cutting-edge materials into their collections. This agility enables brands to respond swiftly to market trends and consumer demands.

- Reduced Risk of Product Failure and Recalls: Using inferior or inconsistently performing materials can lead to product defects, returns, and even costly recalls, severely damaging brand credibility. Partnering with experts minimizes these risks by ensuring the fundamental material integrity.

- Enhanced Brand Reputation and Consumer Trust: High-performance activewear builds trust. When garments consistently deliver on promises of dryness, comfort, and durability, it reinforces a brand’s commitment to quality, fostering loyalty and positive word-of-mouth.

- Supply Chain Efficiency and Reliability: Dedicated performance fabric suppliers typically have robust supply chains optimized for their specialized production. This can lead to more predictable lead times, reduced delays, and smoother production cycles, which is a strategic advantage for manufacturers.

- Sustainability and Ethical Sourcing: Many specialized technical textile suppliers are also leaders in sustainable and ethical manufacturing practices, offering certifications like bluesign or recycled content options. This aligns with increasing consumer demand for environmentally responsible products.

Your Partner in Performance: Sourcing Quality Wholesale Anti-Sweat Fabric

Sourcing quality wholesale anti-sweat fabric is a critical juncture for activewear brands. The right partner in this endeavor offers more than just material; they provide a foundation for innovation, quality, and market differentiation. When seeking a supplier for this specialized cloth material, it is imperative to identify those who understand the nuances of high-performance sportswear. An ideal partner for sourcing quality anti-sweat fabric will exhibit several key attributes:- Extensive Range of Performance Textiles: They should offer a diverse portfolio of anti-sweat fabrics, encompassing various fiber compositions (e.g., polyester, nylon, blends with spandex), construction types (e.g., knits, weaves), and performance enhancements (e.g., different levels of moisture-wicking, antimicrobial finishes). This breadth allows brands to select the precise material for different garment types and activities (Alibaba).

- Technical Expertise in Fabric Applications: A knowledgeable supplier understands how specific fabric properties translate into garment performance. They can advise on the best fabric choices for yoga apparel, running gear, or general activewear, considering factors like stretch, recovery, and drape (Pinecrest Fabrics).

- Commitment to Quality Control: They should have stringent internal quality checks to ensure the fabric meets technical specifications consistently. This includes testing for colorfastness, shrinkage, and long-term performance attributes.

- Scalable Wholesale Solutions: The ability to provide consistent quality and quantity for wholesale orders is paramount. This includes flexible minimum order quantities (MOQs) for development stages and efficient production for larger runs.

- Transparent Sourcing and Certifications: A reliable partner will be transparent about their sourcing practices and offer relevant certifications to validate the quality and sustainability of their fabrics.

Elevate Your Activewear: Making the Right Choice of Garment Fabric Supplier

The success of an activewear brand hinges significantly on the quality and performance of its garments, which are fundamentally determined by the choice of garment fabric. Elevating activewear from generic sportswear to premium, high-performance apparel requires a strategic and informed decision when selecting a specialized supplier for anti-sweat fabric. This choice directly impacts product functionality, consumer satisfaction, and ultimately, brand reputation and profitability. To make the right choice, consider the following actionable steps:- Define Your Specific Fabric Needs: Before engaging with suppliers, clearly articulate the desired performance characteristics for your activewear line. This includes moisture-wicking speed, breathability, stretch, durability, hand-feel, and any specific antimicrobial or UV protection requirements (330 Trading). Precise specifications enable you to filter potential suppliers effectively.

- Prioritize Quality and Testing: Never compromise on quality. Request fabric samples for in-house or third-party testing to verify their performance claims. A reliable supplier will readily provide technical data sheets and support your testing efforts.

- Assess Supplier’s Expertise and Infrastructure: Look for a supplier with a proven track record in performance textiles. Evaluate their manufacturing capabilities, R&D investments, and the technical depth of their team. A supplier with specialized knowledge can offer insights and solutions tailored to your unique brand vision.

- Evaluate Communication and Support: A strong relationship with your fabric supplier is built on clear communication, responsiveness, and collaborative problem-solving. This is crucial for navigating potential challenges in production or development.

- Consider Scalability and Long-Term Partnership: Choose a supplier who can grow with your brand, accommodating increasing order volumes while maintaining consistent quality. A long-term partnership fosters mutual understanding and streamlined processes, enhancing efficiency.

- Focus on Value, Not Just Cost: While cost is a factor, prioritizing the lowest price often leads to compromises in quality and performance. Focus on the overall value—the balance of price, quality, innovation, and reliability—that a specialized supplier offers.

Conclusion

The evolution of activewear demands a sophisticated approach to material sourcing, moving beyond general textiles to highly specialized performance fabrics like anti-sweat material. This article has illuminated the inherent limitations of conventional fabric suppliers in meeting these precise demands and has outlined the critical properties that define true anti-sweat technology. Furthermore, it has provided actionable guidance on selecting specialized fabric suppliers and detailed the profound strategic advantages that such partnerships offer—from ensuring product quality and fostering innovation to strengthening brand reputation. For any activewear brand aspiring to excel in a competitive market, understanding these distinctions and making informed sourcing decisions is not merely an operational choice but a foundational element for achieving product excellence and sustained market success.Sources

Looking For Textile Supplier? Get Wholesale Price From Us Now

![[JuncoMaterials]Why Your Regular Fabric Supplier Can't Handle Anti-Sweat Material (And How to Find One Who Can)](https://materials.juncosports.com/wp-content/uploads/2025/07/image-24.jpg)

![[JuncoSports]Where to Find Affordable Wholesale Fabric Materials Without Sacrificing Quality](https://materials.juncosports.com/wp-content/uploads/2025/07/image-6.jpg)